Special Design for Double Roller Granulator Machine - Rotary Drum Dryer – Exceed

Special Design for Double Roller Granulator Machine - Rotary Drum Dryer – Exceed Detail:

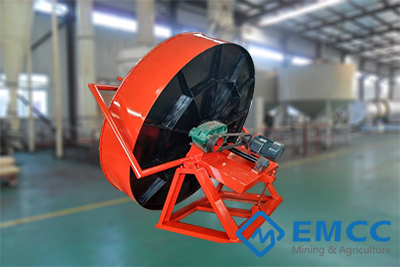

The granular fertilizer formed by the fertilizer granulator has high moisture content and shall be dried to meet the standard. Rotary drum drying machine is mainly used for drying fertilizer with certain humidity and particle size in the compound fertilizer and organic fertilizer production. The dryer drum is also suitable for drying other materials. After drying, the moisture content of compound fertilizer will be reduced to 2%-5% from 20%-30%, while the moisture content reducing range for organic fertilizer is from 40%-10%. Rotary dryer shall be used combining with cooling machine, as fertilizer granules after drying has high temperature, which is not good for storage.

Advantage

1. Rotary drum dryer is suitable for drying granular organic fertilizer and compound fertilizer in the fertilizer production line.

2. Rotary dryer is suitable for drying various animal manure like chicken manure, cow dung, pig manure, duck manure, etc.

3. Rotary drier is suitable for drying crop straw, forage grass, leaves, fish meal, vinasse, herb residue, fruit residue, soy sauce residue, bagasse, turf, sludge, slaughtering leftovers, etc.

4. Rotary dryer is suitable for biomass pellet industry for drying sawdust, wood chips, wood shavings, etc.

Range of Application :

*Suitable for drying of compound fertilizers and other powder and granular materials.

*Suitable for drying of various materials in large-scale fertilizer processing industry, building materials, metallurgy and chemical industry, light industry, medicine and mining industries.

Working principle

Rotary drum dryer adopts slightly tilted drum which can be rotated. The wet materials are sent to hopper of rotary dryer by belt conveyor or bucket elevator from the higher side, and well-dried materials are collected from the other lower side, and hot air enters the drum from the feeding side or discharging side according to user needs.

Technical Parameters

Product detail pictures:

Related Product Guide:

Two minute briefing: Polyhalite and Sirius Minerals | Organic Liquid Fertilizer Manufacturers

Well Dang, Lab-Grown Meat Might Bad For the Planet Too | Organic Fertilizer Products

Attaining consumer satisfaction is our firm's purpose for good. We'll make wonderful efforts to produce new and top-quality merchandise, meet up with your special necessities and supply you with pre-sale, on-sale and after-sale products and services for Special Design for Double Roller Granulator Machine - Rotary Drum Dryer – Exceed, The product will supply to all over the world, such as: Argentina , Algeria , Kuwait , Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.