professional factory for Osb Production Line Machine - Double Shaft Fertilizer Mixer – Exceed

professional factory for Osb Production Line Machine - Double Shaft Fertilizer Mixer – Exceed Detail:

The double shaft Fertilizer Mixer is for large fertilizer mixing capacity. It is newly developed high efficiency powder blending equipment in many fields such as pharmacy,food,organic fertilizer, health care products,dyestuff,building materials,refractory material,resin glass and nuclear materials,etc

Advantage

1. Adopting the novel rotor structure, the minimum clearance between the rotor and shell can be adjusted to nearly zero, which efficiently decreases the residue of materials.

2. This fertilizer mixer is equipped with the pipeline which can add the grease into it. The overall structure of the machine is more reasonable, easy to install and attractive in appearance.

3. It utilizes stainless steel spiral blade with hard steel tool bit, which is durable and good wear resistance. Thus it can prolong the service life of machine.

4. With features of high mixing efficiency, materials can be fully mixed, thus improving the mixing uniformity.

5. It can also crush the larger materials during mixing process.

6. Low energy consumption, low noise, stable performance, easy to operation and maintenance.

7. Suitable for both compound fertilizer and best organic fertilizer production

Range of Application :

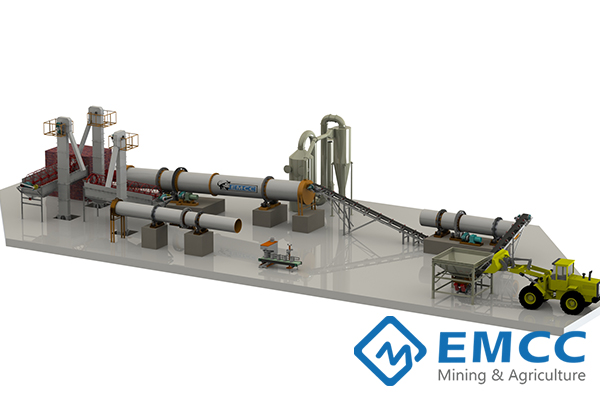

The double shaft works in opposite direction towards the liner direction. They both mix fertilizer particles from the center part to each other’s liner part and cycle like this. The shovels are strong enough to mix 3-15 tons per hour. There are conveyor belt to transfer mixed fertilizer to the next process.

Working principle

There are two main shafts on which welded many small shovels for blending. The shovels are made of robust carbon steel which is thick enough to blend and crush heavy duty fertilizer particles.Horizontal engine drives main shafts rotating. There is polypropylene material coated on the inner liner to prevent corrosion. There is reduction gears matched to ensure stable performance. The tactical design of mixing drum and rotating shafts make materials completely and evenly blending.

Technical Parameters

Product detail pictures:

Related Product Guide:

Indorama Eleme Fertilizer & Chemicals Limited Signs Project Financing Package for US$ 1.2 bln Greenfield Urea Fertilizer Plant | Fertilizer Granulating Machine

Tim’s Tips: When it comes to fertilizer, the options are plentiful | Lifestyles | Fertilizer Granulating Machine

We have been experienced manufacturer. Wining the majority of the crucial certifications of its market for professional factory for Osb Production Line Machine - Double Shaft Fertilizer Mixer – Exceed, The product will supply to all over the world, such as: Costa rica , European , Kuwait , Being the top solutions of our factory, our solutions series have been tested and won us experienced authority certifications. For additional parameters and item list details, be sure to click the button to acquire additional nformation.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.