Professional Design Organic Fertilizer Granules - High Moisture Fertilizer Crusher Machine – Exceed

Professional Design Organic Fertilizer Granules - High Moisture Fertilizer Crusher Machine – Exceed Detail:

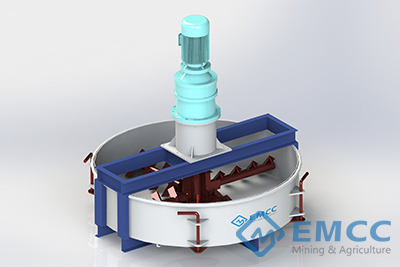

High moisture fertilizer crushing machine is typically designed and applied to wet fertilizer material such as straw, sludge, barks, manures, humic acid,etc. Customers can adjust crushing spaces according to the thickness of fertilizer particles they need. It contains two layers crushing systems which crush the materials finely enough to less than 3 mm; what’s more, it has no strict demands on fertilizer materials and the moisture content can reach about 30%. It is always your option if you are to produce organic fertilizer.

Advantage

1.Suitable to various organic fertilizer production, crushing humid and dry fermented fertilizer.

2.Shorten fertilizer processing stages, reducing cost and investment.

3.High crushing speed,fine and uniform powder fertilizer.

4.No screen design protects motor and machine components.

5.Good lining leather to prevent sticking.

Technical Parameters

| Model | Capacity (t/h) | Power (kw) | Discharge size (mesh) | Dimension (mm) |

| SF-40 | 1-1.5 | 22 | 50 | 1200x1350x900 |

| SF-40II | 1-1.5 | 22×2 | 80 | 1250x1600x1300 |

| SF-60 | 1.5-3 | 30 | 50 | 1300x1450x1300 |

| SF-60II | 1.5-3 | 30×2 | 80 | 1500x2150x1920 |

| SF-90 | 3-5 | 37 | 50 | 1800x1550x1700 |

| SF-90II | 5-8 | 75 | 50 | 2100x2600x2130 |

Working principle

After the crusher works, the organic material can be put into the crushing chamber through the feeding hole. The crushing system of the semi-wet materials crusher consisting of two-stage rotors crushes the organic materials in the crushing chamber in two stages. The organic material is first crushed by the first-stage rotors and then crushed by the second-stage rotors, thus the granularity is fine enough.Besides, the hammers of the crusher are made of high-alloy and hard-wearing metal material to make sure the organic material is crushed well.

After the organic material is crushed enough, the granules are delivered to the discharging hole of the crusher. The semi-wet materials crusher has no screen hole so that various granules can come out from the bottom of the crusher directly without blocking.

Product detail pictures:

Related Product Guide:

Massive structures emerge as CF construction progresses | A1 | Organic Fertilizer Products

Dangote Refinery Will Save Nigeria $26bn Yearly-Expatriate | Fertilizer Granulating Machine

We always get the job done to be a tangible staff to ensure that we can easily offer you the best high-quality and the greatest value for Professional Design Organic Fertilizer Granules - High Moisture Fertilizer Crusher Machine – Exceed, The product will supply to all over the world, such as: Mumbai , Turkey , Uganda , With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.