Professional Design Fertilizer Shaker Screen - Disc Mixer – Exceed

Professional Design Fertilizer Shaker Screen - Disc Mixer – Exceed Detail:

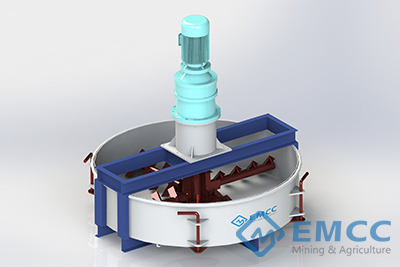

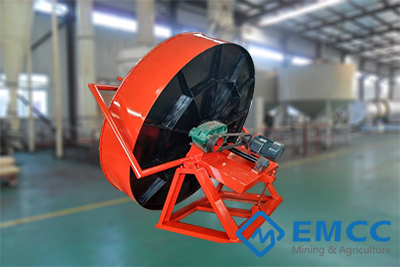

The disc mixer is mainly applied to the compound fertilizer plant. By using the optimum quality material and leading technology, this fertilizer mixing machine complies with industry standards and international specifications. It is popular with our customers due to its high efficiency, competitive price, easy operation and low maintenance cost. In the compound fertilizers production line, it is placed before the fertilizer granulator to uniformly mix the raw materials before the granulation.

Advantage

1. Robust structure. It is made of steel, resistant to abrasion, wear resistance, durable.

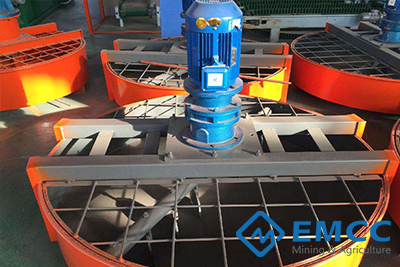

2. Design and rational configuration. PVC padded plate to avoid sticking the inner lining.

3. Cycloidal reducer, high speed and efficiency, energy saving.

4. Mixing and crushing material, easy to operate and unload materials.

5. Can work independently or match with the fertilizer plant.

Principle of Work

The entire mixing process is driven by the main shaft after starting the engine. There are several stirring blades welded on the main shaft and small shovels are placed on each stirring blade. Feed the fertilizers in the cylinder. It is the shovels and the agitation blades that play an important role in the homogeneous mixture of materials. Then open the discharge door to place the average mixed fertilizer. As the material is not very wet, it almost does not stick to the shovels or stirring blades, so it is not necessary to clean the machine.

Technical Parameter

Product detail pictures:

Related Product Guide:

Expert comment: Bridging Kenya’s trade deficit | Organic Liquid Fertilizer Manufacturers

pH Levels and Cancer, Alkaline and Acidic Foods | Organic Fertilizer Plant

We also supply merchandise sourcing and flight consolidation companies. We now have our very own manufacturing facility and sourcing business. We could present you with almost every kind of product relevant to our solution array for Professional Design Fertilizer Shaker Screen - Disc Mixer – Exceed, The product will supply to all over the world, such as: Mongolia , Paris , Norwegian , Look forward to the future, we will focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let's develop market by fully utilizing our comprehensive advantages and strive for building.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!