Professional Design Chicken Manure Fertilizer Grass Pellet Making Machine - 30,000 Tons/year Rotary Drum Granulator Production Line – Exceed

Professional Design Chicken Manure Fertilizer Grass Pellet Making Machine - 30,000 Tons/year Rotary Drum Granulator Production Line – Exceed Detail:

Raw Materials of Organic Fertilizer can be methane residue, agricultural waste, animal manure, and MSW. While all those organic waste need to be further processed before being turned into products with sales value. The large investment in Turning Trash into Treasure is absolutely well worth the money.

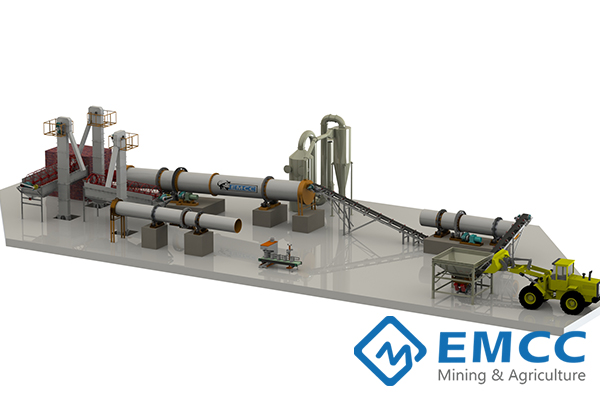

This organic fertilizer production line is equipped with groove type compost turner, rotary drum granulator, chain crusher, rotary drum dryer & cooler, rotary drum screening machine and other auxiliary fertilizer equipment. The annul output can be 30,000 tons. As a professional fertilizer production line manufacturer, we also supply the customers with other granulation lines with different production capacity, such as 20,000 T/Y, 50,000T/Y, and 100,000T/Y, etc.

Advantage

1. Adopts advanced rotary drum granulator, the granulation rate can reach 70%.

2. Key parts adopt wear-resistant and corrosion-resistant materials, the equipment have long service life.

3. Adopt plastic plate or stainless steel plate lining, materials not easy to stick on the inner wall of the machine.

4. Stable operation, easy maintenance, high efficiency, low energy consumption.

5. Adopt belt conveyor to connect the whole line, reliazing continuous production.

6. Adopt two sets of dust settling chamber to deal with the tail gas, environment friendly.

7. Two times of screening process ensure qualified granules with uniform size.

8. Evenly mixing, drying, cooling, and coating, the finished product has superior quality.

Technical Parameters

Raw materials pre-crushing (high moisture fertilizer crusher) → Organic materials fermentation (groove type compost turner) → Fermented materials crushing (high moisture fertilizer crusher)→ Granulating (rotary drum granulator) → Drying (rotary drum dryer) → Cooling (rotary drum cooler) → Finished products screening (rotary drum sifting machine) → Sub-standard granules crushing (vertical fertilizer chain crusher) → Coating (rotary drum coating machine) → Finished products packing (automatic quantitative packager) → Storage (storing in a cool dry

NOTICE: This production line is for your reference only.

Working principle

1. Aerobic Fermentation

Gathering biodegradable raw materials in the working area. Lane turner (groove type fertilizer turner) is used for the fermentation and turning of livestock manure, sludge garbage, straw, sawdust and other organic wastes. Under the operation of vertically and horizontally walking gear, the high-speed disc harrows throw the fermentative materials up, then fall to the ground and the material shift. The fermented material is carried away and the space is cleared for the material requiring fermentation. Thus a complete fermentation process is formed.

2. Materials Crushing

Semi-wet fertilizer crusher, also called high moisture crushing machine, has two smashing systems, which helps to thin material particles below 3mm. It has a low moisture requirement on raw materials, as the allowable water content could be 35%, especially suitable for fermented organic material. High moisture fertilizer crusher is widely used in organic & bio-organic fertilizer production.

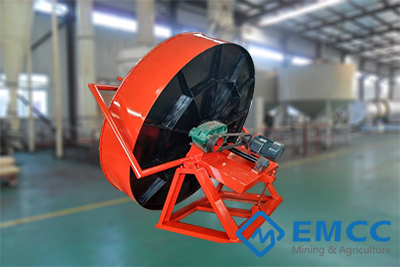

3.Materials Granulating

After crushing, materials are transported into rotary drum granulator by belt conveyor. With the constant rotating of drum, the materials form a rolling bed, and moves along a certain path. Under the extrusion force produced, the materials agglomerate into small particles, which become the core, attaching the powder around to form the qualified spherical granules.

4.Fertilizer Drying

Material shall be dried to enter the dryer. When the dryer is rotating, a series of internal fins will lift the material by lining the inner wall of the dryer. When the material reaches certain height to roll the fins back, it will be fell back to the bottom of the dryer, then passing through the hot gas stream as it falls. Independent air hating system, centralize waste discharge result in energy and cost saving.

5.Fertilizer Cooling

Rotary drum cooler removes fertilizer water and lowers temperature, used with rotary dryer in organic fertilizer and in-organic fertilizer production, which greatly increases cooling speed, and relieves work intensification. The rotary cooler also can be used to cool other powdered & granular materials.

6.Fertilizer sifting

Fertilizers are conveyed into the cylinder through the feed end. With the rotating of the cylinder, organic fertilizers are sifted. Larger granules flowing along the slope of the cylinder to move forward, and the materials are screened through different screens for different purposes. The sub-standard fertilizer granules will be transported back to vertical fertilizer crusher for further process, while the finished products are conveyed to fertilizer coating machine, or directly transported to automatic fertilizer packager.

Product detail pictures:

Related Product Guide:

American Recycler, March 2010 | Fertilizer Wet Mixing Granulator

Halide Minerals Market 2021: Top Key Players Arab Potash Company, Israel Chemicals Ltd. (ICL) | Organic Liquid Fertilizer Manufacturers

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for Professional Design Chicken Manure Fertilizer Grass Pellet Making Machine - 30,000 Tons/year Rotary Drum Granulator Production Line – Exceed, The product will supply to all over the world, such as: Switzerland , Slovakia , Suriname , We will initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.