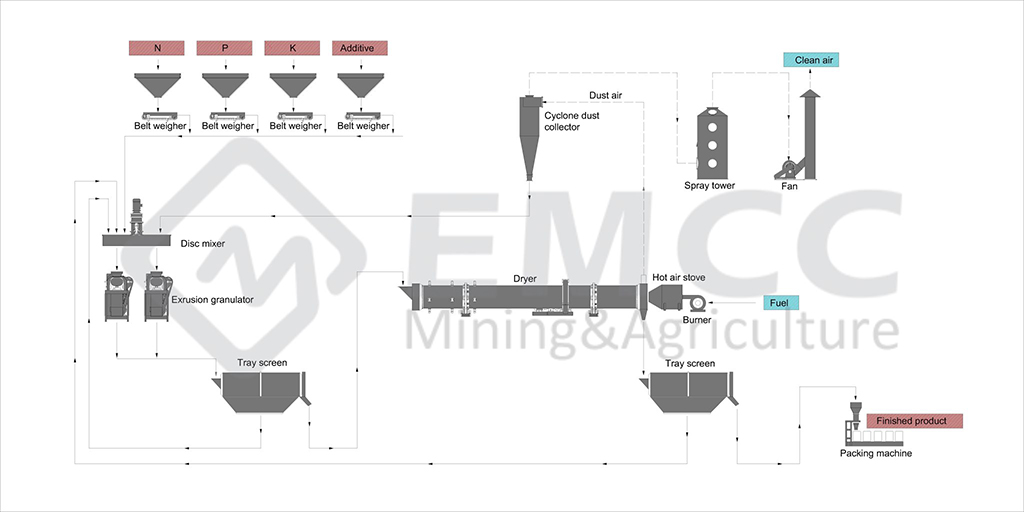

PRESSURE GRANULATION LINE

The extrusion granulation production line is suitable for some specific raw materials. Because it only needs to add a small amount of water during the extrusion granulation process, which will greatly reduce the drying energy consumption of the subsequent process, and even some raw materials do not need to be dried after granulation.

RELATED EQUIPMENT

| Production Line Equipmen | Supporting Equipment | Supporting Environmentally Friendly Dust Removal Equipment |

| Batching System | Crusher | Pulse Dust Collector |

| Roller Granulator | Mixer | Spray Tower |

| Drum Dryer | Elevator | Boiler |

| Drum Cooler | Belt conveyor | Combustion Device |

| Screening equipment | ||

| Coating machine | ||

| Packaging machine |

EXTRUSION GRANULATION PRODUCTION LINE IS ALSO CALLED DRY PRESSURE PELLETISING PRODUCTION LINE

Extrusion Granulation Production line: the raw material from the hopper continuously and uniformly added to the top of the roll, in the continuous rotation of the roll extrusion effect, the powder is extruded into plate, and then in the centrifugal effect and the effect of the plate’s own gravity off, in the crushing function with the impact of the shaping wheel is separated into particles.