Popular Design for Organic Fertiliser Granulator - Double Shaft Chain Fertilizer Crusher – Exceed

Popular Design for Organic Fertiliser Granulator - Double Shaft Chain Fertilizer Crusher – Exceed Detail:

No matter nitrogen fertilizer, phosphatic fertilizer, compound fertilizer and organic fertilizer production, horizontal crushing machine plays its indispensable role in smashing bulk fertilizer raw materials into powder for making fertilizer particles. Our double shaft horizontal crusher is suitable to crush many fertilizer materials like amino acid, cereals, straws, fish powder, sludge etc. whose moisture content is about 14% and 6% free acid content. It is popular in any size fertilizer plant, and we have always been researching and developing fertilizer equipmentbased on convenience tenet.

Advantage

1.Chains are of high strength and wear-resistant alloy material,solid bearings and durable.

2.Fine and uniform powder size,least sticking to crushing chamber.

3.Simple operation,high speed and efficiency,large crushing capacity.

4.Advanced roller design,ensure enough space for completely crushing.

5.Easy to maintain, fit for continuous working

Working principle

The horizontal crusher body mainly consists of motor,rotating shaft,crushing chains,chamber,etc. The motor offers power for rotating shafts and the circular chains hung on the main shafts rotate in the opposite way. Between the two main shafts is crushing area. The fertilizer materials fell down are smashed and discharged from the bottom of the crusher. The crushed fertilizer powder fine and uniform with the size range of 0.7mm-4mm and the crushing rate is above 95%, with the moisture content of less than 6%.

Technical Parameters

Product detail pictures:

Related Product Guide:

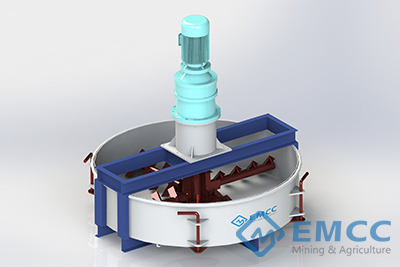

Addressing Sulfur Deficiencies in Wheat | Fertilizer Wet Mixing Granulator

Halide Minerals Market key manufacturers Agrium Inc., Arab Potash Company, Israel Chemicals Ltd. (ICL) | Organic Fertilizer Products

Our growth depends on the superior equipment ,exceptional talents and continuously strengthened technology forces for Popular Design for Organic Fertiliser Granulator - Double Shaft Chain Fertilizer Crusher – Exceed, The product will supply to all over the world, such as: Sevilla , Tajikistan , Egypt , Make sure you genuinely feel free to send us your requirements and we are going to respond for you asap. We now have got a skilled engineering group to serve for your just about every detailed needs. Cost-free samples could be sent to suit your needs personally to understand much more information. In an effort to meet your requires, be sure to seriously feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd objects. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is really our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

We have been looking for a professional and responsible supplier, and now we find it.