Original Factory Dry Granulation Roller Compactor - Rotary Drum Cooler – Exceed

Original Factory Dry Granulation Roller Compactor - Rotary Drum Cooler – Exceed Detail:

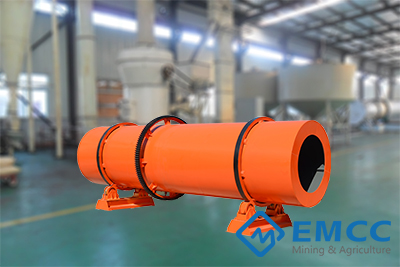

Our rotary drum cooler is regularly used to cool fertilizers with a certain temperature and granularity in compound fertilizer production lines. The inlet temperature of materials generally is 60 °~ 80°, the outlet temperature is less than 40°. It is always used in combination with the drying machine to greatly increase cooling speed, improve the cooling rate and product quality, and further remove the water and reduce fertilizer particle temperature.

Advantage

1. Compact structure, easy maintenance, reliable performance, low energy consumption.

2. Rational distribution and angle of lifting plates maximize heat transfer between materials and cooling air, improving cooling efficiency and achieving evenly cooling effect.

3. Strong adaptability, suitable for processing granules with a broad particle size distribution.

4. Multiple models available for your choice, and also can be customized.

5. The rotating speed of the cylinder can be adjusted according to your requirement.

6. Adopt high quality wear-resistant materials, ensure long service time of the machine.

Working principle

1. The main motor drives the belt and belt pulley, and transfers to the driving shaft through the reducer. The pinion which is installed on the driving shaft engages with the gear fixed on the machine body, working in the opposite direction to make the cylinder rotate.

2. The rotary drum is slightly slanted with an angle of 2-5°. By the belt conveyor, the hot fertilizer from the dryer is sent into the drum cooler through the feed hopper at the higher end. Meanwhile, under the suction of the draught fan at the feed end, the air flow inside the cylinder speeds up.

3. With the rotation of the cylinder, the materials flow down to the lower end with the effect of gravity. The lifting plates installed on the inner wall of the cylinder lift the granular materials continuously, forming a uniform material curtain, which counter current contact with the suction cool air and exchange heat, the temperature of the materials is reduced, achieving the aim of cooling and further reducing the moisture. The cooled materials flow out from the lower end of rotary drum and are sent to the rotary screener by the belt conveyor. The tail gas enters into the dust settling chamber.

Technical Parameters

Product detail pictures:

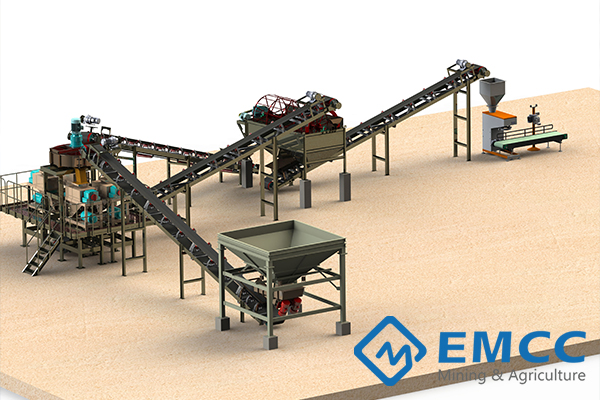

Related Product Guide:

Sulfuric Acid Market Accounted Billions of Dollar Business With Growing CAGR of 3.0% by 2024 | Fertilizer Granulating Machine

Potassium Hydroxide Market 2019 with top countries data : Cost Analysis, Regions, Key Players, Manufacturers Analysis, Application and Specification, Price and Gross Margin by 2024 | Organic Liquid Fertilizer Manufacturers

We offer fantastic energy in high quality and enhancement,merchandising,profits and promoting and procedure for Original Factory Dry Granulation Roller Compactor - Rotary Drum Cooler – Exceed, The product will supply to all over the world, such as: Cancun , Romania , Kenya , In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we are going to continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.