OEM manufacturer Microelement Fertilizer - Rotary Drum Screen – Exceed

OEM manufacturer Microelement Fertilizer - Rotary Drum Screen – Exceed Detail:

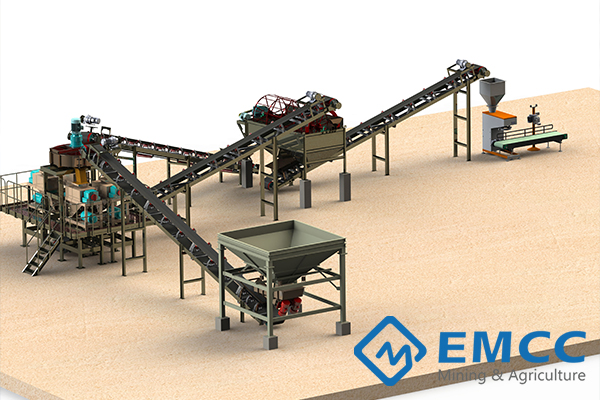

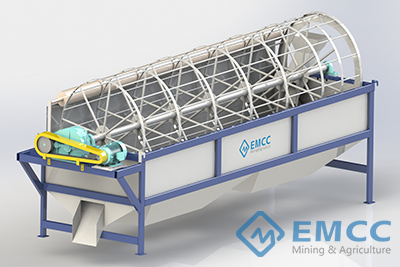

In fertilizer production, the fertilizer granular shall be screened before packaging to ensure the uniformity of the finished product. Rotary drum screen is a common equipment used in the fertilizer industry for compound fertilizer and organic fertilizer production. Rotary durm screen is mainly used in the fertilizer production line to separate finished product and returning materials. The fertilizer sieving machine can also be used for classifying the finished product.

Advantage

1. Adopt combined screen which is easy for maintenance and replacement.

2. High screening efficiency, reducing labor intensity.

3. The driving part adopts pin coupling, making it convenient for assembly and maintenance.

4. Reasonable structure, stable operation, no damage to the rotary machine.

5. Sealed dust cover is installed outside the rotary sieve, eliminating flying dust, improving the working environment.

6. The sealed dust cover also helps isolate the noise produced during operation.

7. Being used in organic & compound fertilizer production lines, behind fertilizer cooling machine.

Range of Application :

Rotary drum screen is used in many industries such as fertilizer production, steel making, mining, quarrying, foundries, food processing and chemical industry for the separating of bulk materials like compound fertilizers, organic fertilizers, stone aggregates, different kind of sand, active carbon and other materials.

Working principle

Rotary drum screen consists of five parts, including hexagonal drum, rack, funnel, reducers and motor. After the fertilizer granules go into the drum, it is screened by the rotating of the drum, and on the other hand, granules with large size move forward along the drums gradient, screened gradually through different screen.

Technical Parameters

Product detail pictures:

Related Product Guide:

How to grow sweet peas | Fertilizer Wet Mixing Granulator

Turkish Gubretas, SOCAR Turkey Energy to create joint venture | Fertilizer Wet Mixing Granulator

Our mission is to become an innovative supplier of high-tech digital and communication devices by providing value added design, world-class manufacturing, and service capabilities for OEM manufacturer Microelement Fertilizer - Rotary Drum Screen – Exceed, The product will supply to all over the world, such as: Hamburg , Greece , Ireland , We will supply much better products with diversified designs and professional services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!