OEM manufacturer Fertilizer Vertical Crusher - 30,000 tons/year Extrusion Granulator Line – Exceed

OEM manufacturer Fertilizer Vertical Crusher - 30,000 tons/year Extrusion Granulator Line – Exceed Detail:

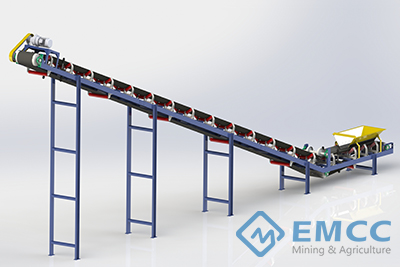

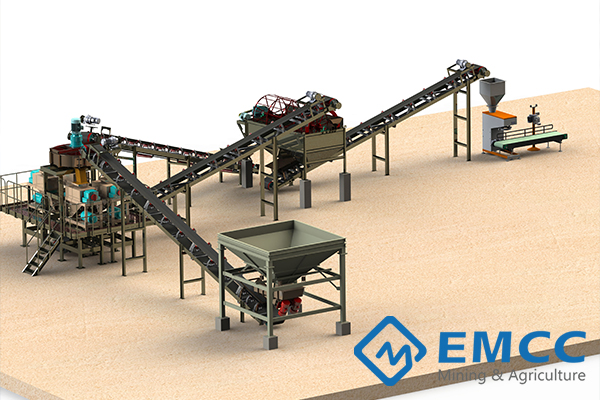

This 30,000 tons/year extrusion granulator production line can produce high, medium and low concentrated compound fertilizer for various crops. With the double granulator to produce the granules, the production line doesn’t need drying process, having small investment and low power consumption. The press rollers of the granulator can be designed to make different shapes and sizes of materials.The line includes automatic batching machine, belt conveyors, pan mixers, pan feeder, extrusion granulators, rotary screening machine, finished products warehouse, and automatic packing machine. We are ready to offer the most reliable fertilizer equipment and the most suitable solutions for our esteemed customers.

Advantages

1. Adopt mechanical pressure to form the granules, no need to heat or humidify raw materials

2. Suitable for heat sensitive materials, such as ammonium bicarbonate

3. No need for drying process, low investment, low power consumption.

4.No waste water or waste gas emission, no environmental pollution.

5. Uniform particle size distribution, no segregation and agglomeration.

6. Compact layout, advanced technology, stable operation, easy maintenance.

7. Easy operation, easy to realize automatic control, increasing production efficiency.

8. Wide raw materials application range, no special properties requirement

Working principle

1. Automatic Batching Machine

Firstly, various materials are proportioned as per the formula by the 5 bins batching machine, which can complete materials batching automatically with high accuracy and high efficiency, thus the quality of the fertilizer is ensured. After batching, the materials are conveyed to the pan mixer.

2. Disc Mixer

We adopt two sets of disc mixers in this fertilizer production line. The cycloidal reducer drives the main shaft to rotate, and in turn drives the agitating arms. With the stirring of agitating arms and small shovels on them, the raw materials are fully mixed. After mixing, the materials are discharged from the outlet at the bottom. The inner side of the disc adopts polypropylene plate or stainless steel, which makes the materials not easily sticky, and abrasion resistance.

3. Double Roller Fertilizer Granulator

By the belt conveyor, the well mixed raw materials are conveyed to the pan feeder, which feeds the materials evenly into the four extrusion granulators under the feeder through the hopper. By the counter-rotating high pressure rollers, the materials are extruded into slices. The slices flow down to the crushing chamber under the press roller, where they are crushed by the crushing rollers and screened to get the required granular. The press rollers adopt new type metal which is resistant to corrosion, wear and impact.

4. Rotary Screening Machine

By the belt conveyor, the granules from the extrusion granulator are sent to the rotary screening machine, where unqualified granules pass through the screen aperature and discharge through the outlet at the bottom, then conveyed back to the pan feeder, while qualified granules flow out through the outlet at the lower end of the machine and conveyed to the finished products warehouse.

5. Automatic Packing Machine

Through the finished products warehouse, the qualified granules are weighed and packed by the automatic packing machine. The unit consists of automatic weighing and packing machine, conveying device, sealing device and feeder. It has the features of high weighing precision, stable operation, low power consumption, and small land occupancy.

Product detail pictures:

Related Product Guide:

Growing and Caring for Organic Strawberries | Fertilizer Wet Mixing Granulator

A power liquid fertiliser off the sheep’s back | Fertilizer Granulating Machine

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future alongside one another with your esteemed enterprise for OEM manufacturer Fertilizer Vertical Crusher - 30,000 tons/year Extrusion Granulator Line – Exceed, The product will supply to all over the world, such as: Milan , Istanbul , Durban , With the support of our highly experienced professionals, we manufacture and supply best quality products. These are quality tested at various occasions to ensure only flawless range is delivered to customers, we also customize the array as per the need of customers to meet the requirement of customers.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,