OEM Customized Rotary Nickel Screen - Belt conveyor – Exceed

OEM Customized Rotary Nickel Screen - Belt conveyor – Exceed Detail:

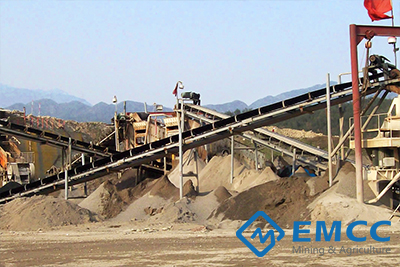

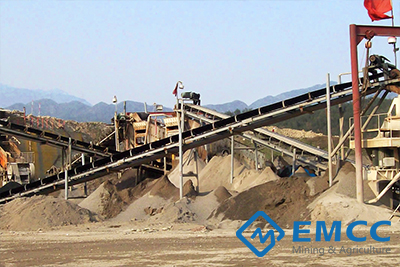

Belt Conveyor System is an indispensable part in the whole fertilizer production line. We provide customers with inclined belt conveyor and high inclination-angle belt conveyor. The inclined conveyor connects main fertilizer equipment together, making an easier raw materials & finished products transportation. The material handling conveyors are used in incline and decline applications to allow fertilizers to be accumulated while moving between floors or stacked conveyor. It saves labor, time and energy, with characters of high efficiency & easy operation. Inclined conveyor is widely used not only in compound & organic fertilizer production, but in wood & feed pellets production line, which is adjustable in accordance with customer demands. The material is discharged into the hopper of the conveyor. This intake hopper has rubber-closing plates to reduce material loss. When worn out, these plates can easily be removed. The inclined belt conveyor is built up of chopped stainless steel. The frame exists of sections that are bolted together. The conveyer belt is on hot sale.

Advantage

1. Compact design, suitable for grain, powder or fertilizer products.

2. Grooves used to fasten attachment parts, such as stands, side rails or proximity switches

3. Profile design ensures a torsion-resistant structure with good carrying characteristics

4. Crowned pivot rollers and idler rollers allow center belt run and facilitate belt adjustment

5. Optional rubberized drive rollers ensure optimal transmission of torque

Working principle

Belt conveyor is composed of rollers and closed conveyor belt. There are two rollers one is for driving conveyor rotating another one is for changing the motor direction of conveyor. Head roller is drived by motor conveyor is draged by force of friction which is generated from head roller and conveyor. Head roller is often set in the discharging end to increase traction for a better dragging. Material is fed from feed end and falls on the rotating conveyor belt and discharged by conveyor delivery end.

Technical Parameters

| Belt Width(mm) | Belt Length(m)/Power(kw) | Belt Speed(m/s) | Capacity(t/h) | ||

| 400 | ≤12/1.5 | 12-20/2.2 | 20-25/3 | 0.8-2 | 40-80 |

| 500 | ≤12/3 | 12-20/4 | 20-30/5.5 | 0.8-2 | 78-191 |

| 650 | ≤12/4 | 12-20/5.5 | 20-30/7.5 | 0.8-2 | 131-323 |

| 800 | ≤10/4 | 10-15/5.5 | 15-25/7.5 | 1.0-2 | 278-546 |

| 1000 | ≤10/5.5 | 10-20/7.5 | 20-25/11 | 1.0-2 | 435-853 |

| 1200 | ≤10/7.5 | 12-20/11 | 20-25/15 | 1.0-2 | 655-1284 |

| Note:actual power will be decided by the complete set | |||||

Product detail pictures:

Related Product Guide:

Too much fertilizer can dry out plant tissue | Fertilizer Granulating Machine

Dangote Refinery project to boost activities in downstream, says LCCI | Fertilizer Granulating Machine

We are commitment to offer the competitive price ,outstanding products quality, as well as fast delivery for OEM Customized Rotary Nickel Screen - Belt conveyor – Exceed, The product will supply to all over the world, such as: Ghana , Gabon , Hamburg , We are very responsible for all details on our customers order no matter on warranty quality, satisfied prices, quick delivery, on time communication, satisfied packing, easy payment terms, best shipment terms, after sales service etc. We provide one-stop service and best reliability to our every customers. We work hard with our customers, colleagues, workers to make a better future.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.