OEM China Kinds Of Organic Fertilizer Production - Dry roll press granulator – Exceed

OEM China Kinds Of Organic Fertilizer Production - Dry roll press granulator – Exceed Detail:

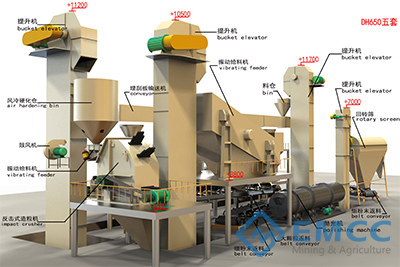

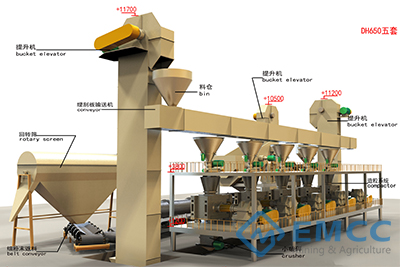

DH series dry roll press granulator adopts dry rolling technology to compress the powdery materials with moisture content ≤ 5% into pieces or tablets, then going through the processes of breaking into granules and screening to make the lump materials into granules that meet the requirements of application. Dry roll press granulator mainly depends on the manner of external pressure to force the material going through the gap between two relatively turning rollers to compress into laminar particles. During course of roller pressing, the real density of materials can increase 1.5~3 times thus reaching certain demands of granular strength.

Product detail pictures:

Related Product Guide:

South Jersey sewage plant makes energy from wind, solar — and meatball grease | Organic Liquid Fertilizer Manufacturers

Bioenergy Byproduct to Soil Savior | Organic Fertilizer Plant

We not only will try our greatest to offer superb companies to just about every buyer, but also are ready to receive any suggestion offered by our shoppers for OEM China Kinds Of Organic Fertilizer Production - Dry roll press granulator – Exceed, The product will supply to all over the world, such as: Philippines , Surabaya , Johannesburg , We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!

Write your message here and send it to us

Write your message here and send it to us