Different organic fertilizer granulation processes require different types of granulators, which directly affect the production, quality, appearance and price of the product. It can be said that the organic fertilizer granulator is the core of the whole production line. Which granulator is suitable for composting?

First of all, let’s talk about the advantages and disadvantages of each type of granulator, and we will give you a reference when choosing a granulator.

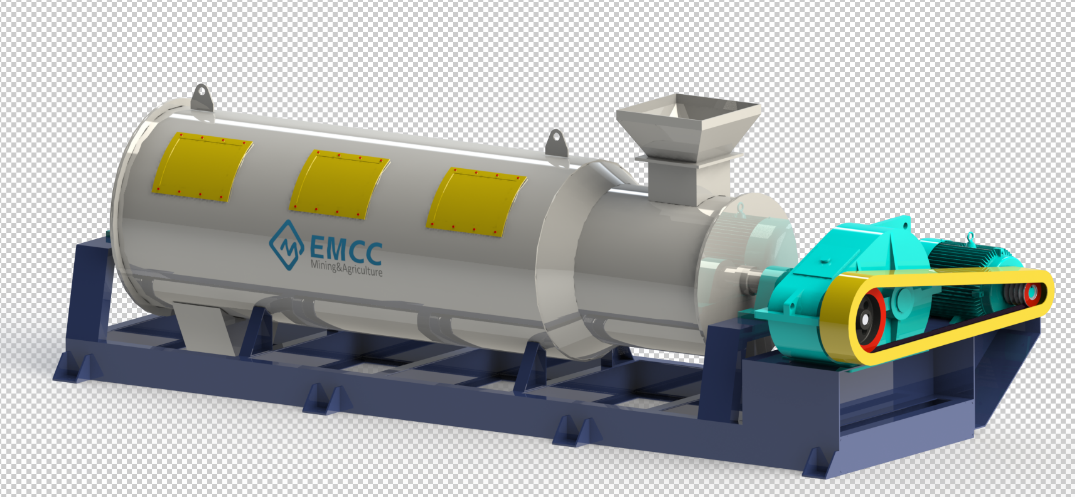

Double Roller Fertilizer Granulator

Double Roller Fertilizer Granulator is a dry granulator, no drying process, high granulation density, good fertilizer efficiency and total organic matter content. It saves the cost of buying dryers and refrigerators, and there is no need to burn charcoal in the later stage, saving a lot of money. However, the shape of the granules of the extrusion granulator is flattened, which is easy to jam when the field cultivating machine is sowing, and the fluidity is not very good. Therefore, this granulation process should be used with caution if it is for organic fertilizers produced by machine-seeded farmers. It is recommended to use this granulator when making compound fertilizers and compound fertilizers..jpg)

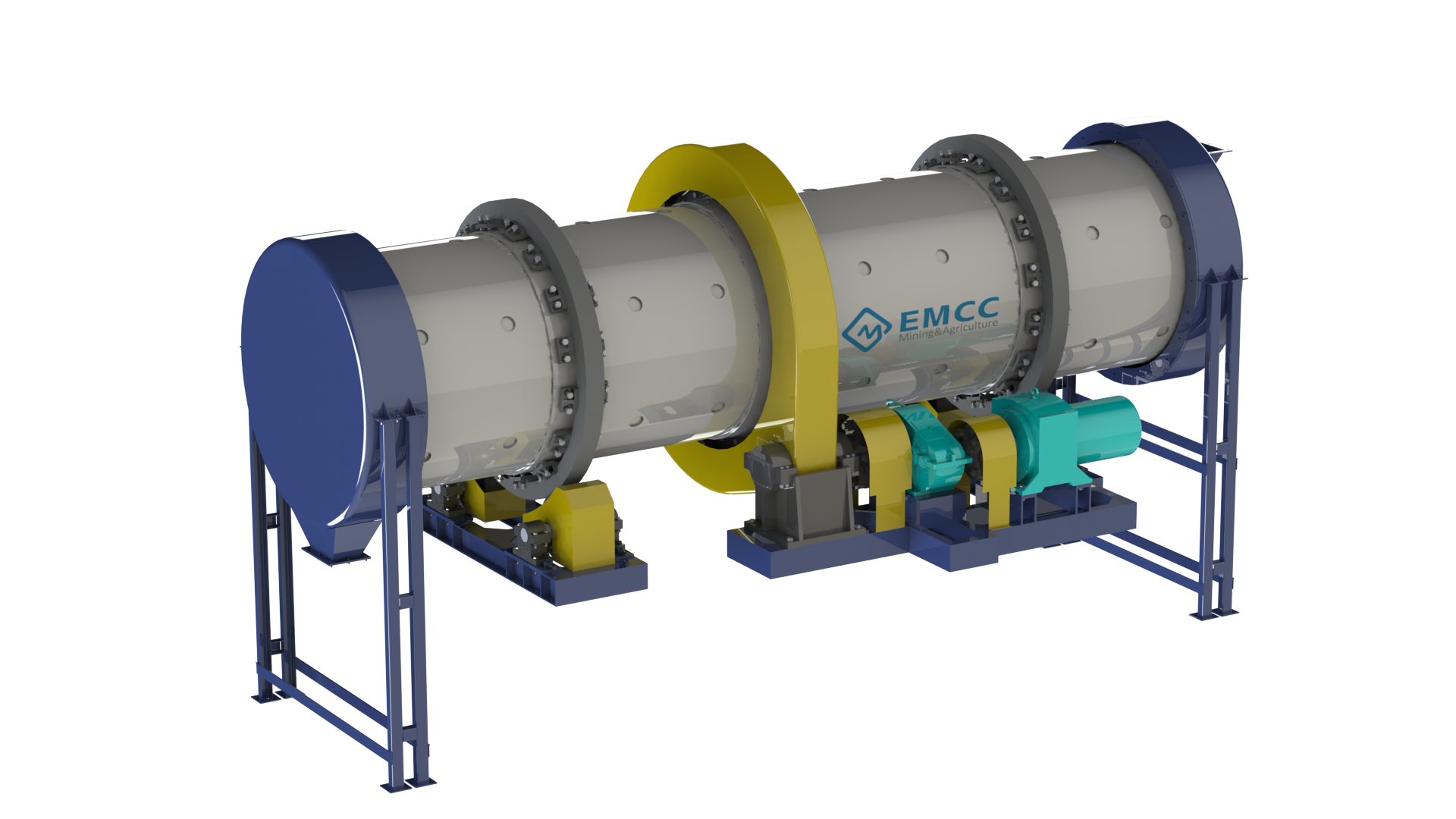

Rotary Drum Fertilizer Granulator

Rotary Drum Fertilizer Granulator is a process that has been used for the granulation of compound fertilizers. It can also be used to produce organic fertilizers, but the granulation rate is low. If you produce organic, inorganic and organic fertilizers, you can choose this process.

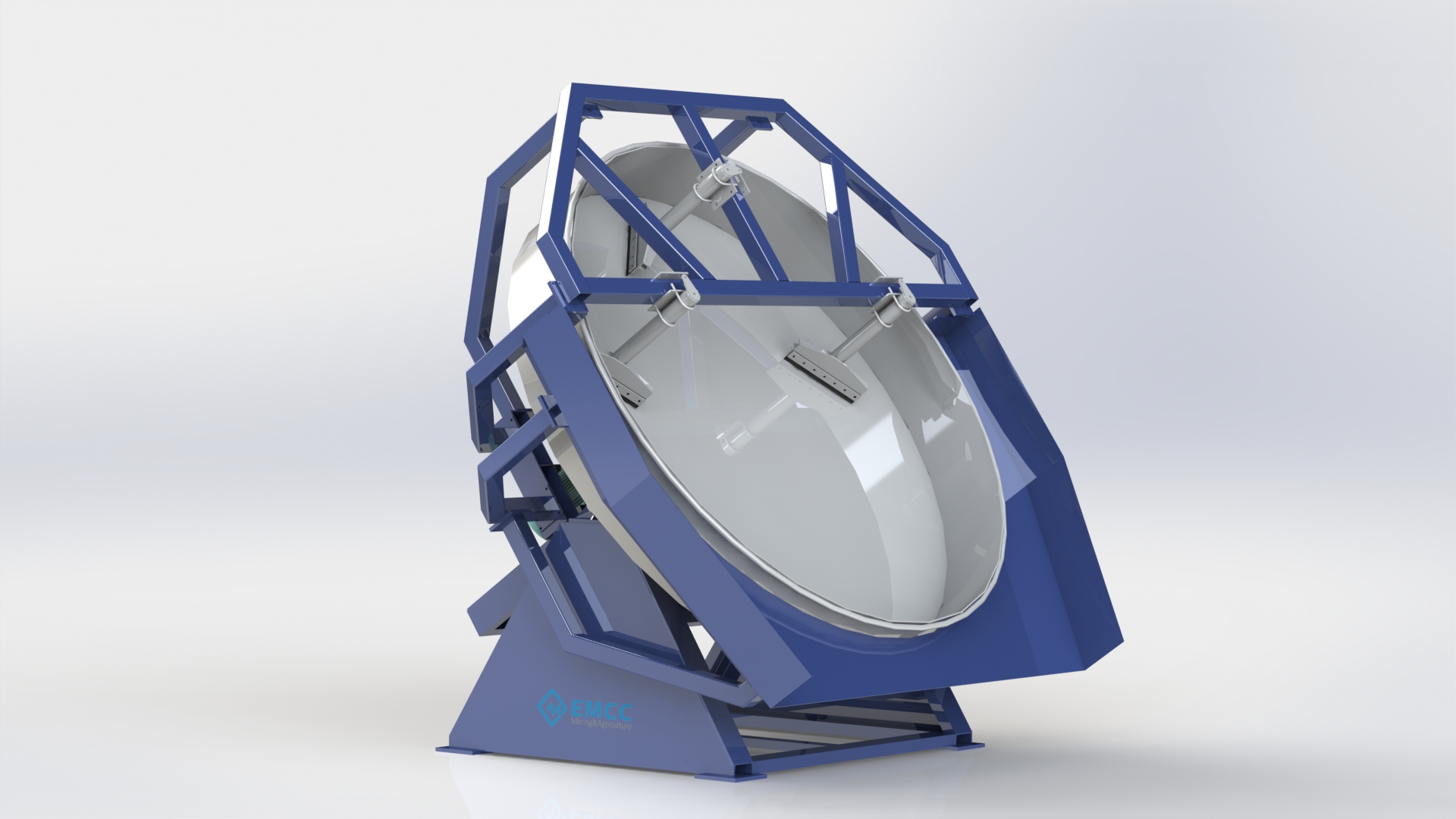

Disc Fertilizer Granulator

Disc Fertilizer Granulator is a more traditional granulation process. I personally admire this type of granulator, which has smooth granulation, good appearance and low equipment price, the only disadvantage is its low density. At present, people are following new and new granulation methods, so the users are declining.

Agitating Organic Fertilizer Granulator

Agitated organic fertilizer granulator, this kind of granulator is now the most popular product on the market, and it is also a preferred product by customers. This type of process has high throughput and smooth processing. If you add organic fertilizer rounding machine, produce the granules are comparable to disk granulation. But you need to buy a dryer and a cooler. Therefore, the entire set of equipment for this process is more expensive.

The above are the advantages and disadvantages of conventional granulation processes on the market. Looking here, I think everyone will be able to choose a suitable granulator.

Post time: Apr-16-2021