New Delivery for Woven Polypropylene Rolls - Disc Mixer – Exceed

New Delivery for Woven Polypropylene Rolls - Disc Mixer – Exceed Detail:

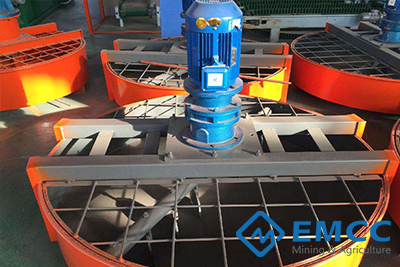

The disc mixer is mainly applied to the compound fertilizer plant. By using the optimum quality material and leading technology, this fertilizer mixing machine complies with industry standards and international specifications. It is popular with our customers due to its high efficiency, competitive price, easy operation and low maintenance cost. In the compound fertilizers production line, it is placed before the fertilizer granulator to uniformly mix the raw materials before the granulation.

Advantage

1. Robust structure. It is made of steel, resistant to abrasion, wear resistance, durable.

2. Design and rational configuration. PVC padded plate to avoid sticking the inner lining.

3. Cycloidal reducer, high speed and efficiency, energy saving.

4. Mixing and crushing material, easy to operate and unload materials.

5. Can work independently or match with the fertilizer plant.

Principle of Work

The entire mixing process is driven by the main shaft after starting the engine. There are several stirring blades welded on the main shaft and small shovels are placed on each stirring blade. Feed the fertilizers in the cylinder. It is the shovels and the agitation blades that play an important role in the homogeneous mixture of materials. Then open the discharge door to place the average mixed fertilizer. As the material is not very wet, it almost does not stick to the shovels or stirring blades, so it is not necessary to clean the machine.

Technical Parameter

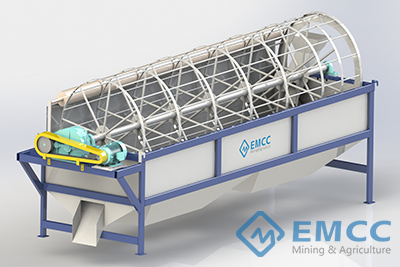

Product detail pictures:

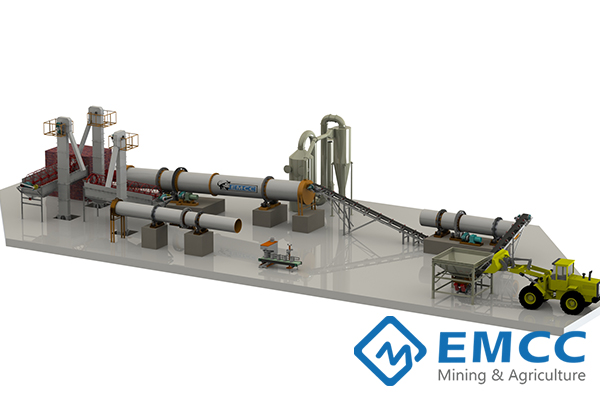

Related Product Guide:

Well Dang, Lab-Grown Meat Might Bad For the Planet Too | Organic Fertilizer Plant

Global Biofungicides Market Outlook 2019-2027 : Bayer Cropscience, DOW Chemical Company, Monsanto Company, BASF, Marrone Bio Innovations | Organic Fertilizer Plant

Our progress depends around the innovative machines, great talents and consistently strengthened technology forces for New Delivery for Woven Polypropylene Rolls - Disc Mixer – Exceed, The product will supply to all over the world, such as: Victoria , South Africa , Salt Lake City , We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. Now we have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our solutions have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We're making great efforts to achieve this win-win situation and sincerely welcome you to join us.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!