Manufacturer of Chemical Fertilizer Granulator Machine - Double Roller Fertilizer Granulator – Exceed

Manufacturer of Chemical Fertilizer Granulator Machine - Double Roller Fertilizer Granulator – Exceed Detail:

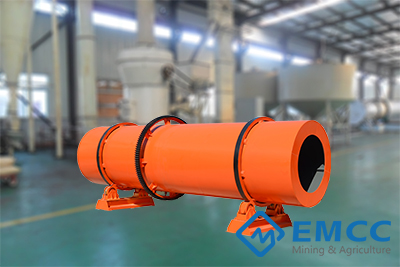

Double roller fertilizer granulator is a newly developed granulating machine in fertilizer industry. It uses squeezing principle to form fertilizer particles with diameters of 3.5-10mm in one time.It has higher granulating ratio of over 85%. Double roller fertilizer granulator is the most popular granulating methods in no-drying (2%-5% moisture content) fertilizer process at room temperature.Less cost and quick granulating,thus it can bring fertilizer investment a good economic returns.

Advantage

1.No-drying fertilizer such as 2%-5% moisture content fertilizer granulating process,forming fertilizer particles in one time,little cost.

2.Reliable motor adopted, no three wastes released,stable granulating,simple to maintain.

3.Rational structure and advanced technology,good economic benefits.

4.Wide application to raw materials like compound fertilizer,organic fertilizer,feed,etc. Can be used to process compound fertilizer of various concentrations(including organic fertilizer,inorganic fertilizer,biological fertilizer and magnetic fertilizer)

5.Popular in domestic fertilizer series production such as tombarthite fertilizer,ammonium bicarbonate fertilizer,ammonium persulfate fertilizer,etc.

Working principle

The Double roller fertilizer granulator is the representative of extrusion granulator. Dry materials are compressed into hard & dense blocks at a pressure, which is the Extruding Process. Block materials are crushed, screened and granulated later, which is the Granulating Process. The functions of extrusion are to squeeze the air between particles out, and to make the distance between particles near enough to give rise to interaction forces. The particle hardness of roller compaction granulation granules is formed mainly due to attraction between the molecules. Our double roller press machine is continuous extruding granulation of positive-displacement.

Technical Parameters

Product detail pictures:

Related Product Guide:

Organic Fertilizers Market by Source, Form, Crop Type, and Region | Organic Fertilizer Plant

No-Till Farmer Editors Share Top News Makers from National Farm Machinery Show | Organic Fertilizer Plant

Sticking to the principle of "Super High-quality, Satisfactory service" ,We are striving to generally be a very good business partner of you for Manufacturer of Chemical Fertilizer Granulator Machine - Double Roller Fertilizer Granulator – Exceed, The product will supply to all over the world, such as: Portugal , Cannes , Lithuania , Due to good quality and reasonable prices, our products have been exported to more than 10 countries and regions. We are looking forward to cooperating with all customers from at home and abroad. Moreover, customer satisfaction is our eternal pursuit.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.