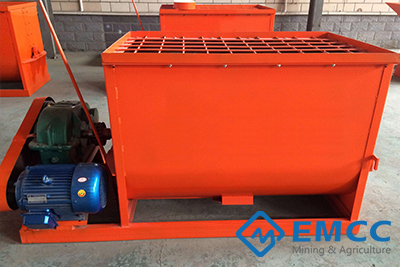

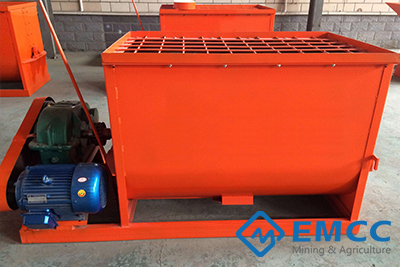

Manufacturer for Animal Feed Pellet Press Granulator - Horizontal Fertilizer Mixer – Exceed

Manufacturer for Animal Feed Pellet Press Granulator - Horizontal Fertilizer Mixer – Exceed Detail:

The horizontal fertilizer mixer, which is the new-generation mixing equipment developed by our factory, is high mixing uniformity, less material residual. This kind of fertilizer mixing machine is suitable for blending the formula feed, concentrated feed, additive premix, and raw materials of organic and compound fertilizer

Advantage

1.Multifunctional.Applied to many heavy industry fields such as chemicals,pharmacy,food,fertilizer,dyestuff,construction materials,resin glass,ect.

2.High mixing speed and uniformly mixing,low noise.

3.Reduction gears is matched to make sure stable mixing.

4.Carbon steel materials,durable and simple maintenance cost.

5.Low energy consumption,simple operation.

Range of Application :

This kind of fertilizer mixing machine is suitable for blending the formula feed, concentrated feed, additive premix, and raw materials of organic and compound fertilizer.

Working principle

1. Ensure to check whether the bolts are loose or not before starting the machine.

2. To check the bearing block and reduction drive. To see if their oil level is in place.

3. It is strictly prohibited that the materials with the big stone, big iron and etc, to avoid damaging the mixing blade.

4. Before stopping the machine, we should first stop feeding materials. It forbids to stop the machine with materials in it.

5. Starting the main motor, to check if the direction of rotation is opposite. If opposite, stop and adjust the machine immediately.

6.This machine should be started under the circumstance of zero load. It is strictly forbidden to put raw materials in the mixer before it rotating, to avoid damage to the machine.

7. Widely used in flat die granulator production line and new type organic fertilizer production line

Technical Parameters

| Model | Mixing speed (r/min) | Reducer model | Plate thinkness (mm) | Capacity(t/h) | Power (kw) | Dimension (mm) | |

| WJ-7015 | 46 | ZQ350-23.34 | 4 | 2-3 | 7.5 | 2350x1200x1000 | |

| WJ-9015 | 39 | ZQ350-23.34 | 4 | 3-5 | 11 | 2350x1200x1000 | |

| WJ-1630 | 21 | ZQ3500-48.57 | 10 | 10-15 | 22 | 3950x1720x2100 | |

Product detail pictures:

Related Product Guide:

Plant Sourced Organic Fertilizer Market 2019: Industry Growth, Competitive Analysis, Future Prospects and Forecast 2025 | Organic Fertilizer Plant

Mirimichi looks to changing landscape | Fertilizer Granulating Machine

With this motto in mind, we have turn out to be amongst probably the most technologically innovative, cost-efficient, and price-competitive manufacturers for Manufacturer for Animal Feed Pellet Press Granulator - Horizontal Fertilizer Mixer – Exceed, The product will supply to all over the world, such as: Tanzania , Portugal , Chile , With good quality, reasonable price and sincere service, we enjoy a good reputation. Products are exported to South America, Australia, Southeast Asia and so on. Warmly welcome customers at home and abroad to cooperate with us for the brilliant future.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!