Manufacturer for Agricultural Crystal Monoammonium Phosphate - Rotary Drum Fertilizer Granulator – Exceed

Manufacturer for Agricultural Crystal Monoammonium Phosphate - Rotary Drum Fertilizer Granulator – Exceed Detail:

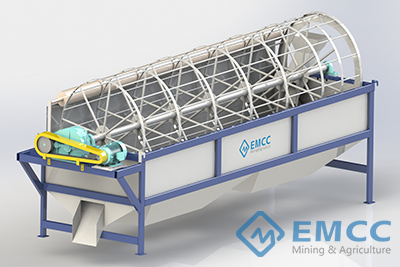

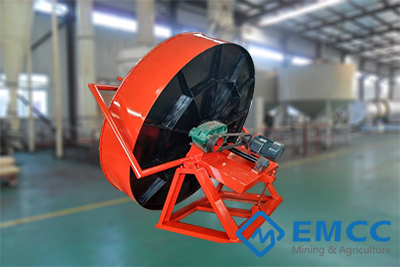

Rotary drum fertilizer granulator is one of the critical machines in compound fertilizer production line. It is applied to cold,hot granulation and quantity production of high,medium or low concentration compound blending fertilizer. The granulating method is rolling round fertilizer particles in wet granulation. With water or vapour added, the original fertilizer in rotary drum are blended uniformly and become humid, during this process, the fertilizer reacts and by way of the liquid environment and rotation in drum, the fertilizer particles squeeze each other and roll into fertilizer particles.The formed fertilizer particles are of 3-4mm.

Advantage

1.High fertilizer particles rolling rate about 70%, less returning fertilizer created,but can be regranulated.

2.Vapour or water adding improves fertilizer temperature and creates high quality fertilizer particles.

3.Engineering plastics are used for inner lining, no stick to liners,Anti-corrosion and thermal insulation.

4.Large granulating capacity,low enrgy consumption and low maintenance cost.

5.Flexible fertilizer particles diameter according to different formulation, processing procedure and raw materials.

6.Super quality steel materials,strict quality requirements and control.

7.Low noise,stable performance;rational structure like shoveling plates to clean drums.

Working principle

The raw materials enter into the rotary drum granulator by the belt conevyor. With the constant rotating of drum, the materials form a rolling bed, and moves along a certain path. Under the extrusion force produced, the materials agglomerate into small particles, which become the core, attaching the powder around to form the qualified spherical granules. The rotary drum is placed obliquely, the granules formed flow out through the outlet of the granulator. The shovelling plates inside the drum help granulating and cleaning

Technical Parameters

Product detail pictures:

Related Product Guide:

What organic fertilizers mean to plants and soil | Organic Fertilizer Plant

Global Optical Network Equipment Market Price | Fertilizer Wet Mixing Granulator

Our personnel are generally within the spirit of "continuous improvement and excellence", and using the excellent top quality goods, favorable rate and superior after-sales expert services, we try to win every customer's believe in for Manufacturer for Agricultural Crystal Monoammonium Phosphate - Rotary Drum Fertilizer Granulator – Exceed, The product will supply to all over the world, such as: United States , Sevilla , Netherlands , Many years of work experience, we have now realized the importance of providing good quality products and solutions and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.