Low MOQ for Plastics Recycling Granulator - Rotary Drum Screen – Exceed

Low MOQ for Plastics Recycling Granulator - Rotary Drum Screen – Exceed Detail:

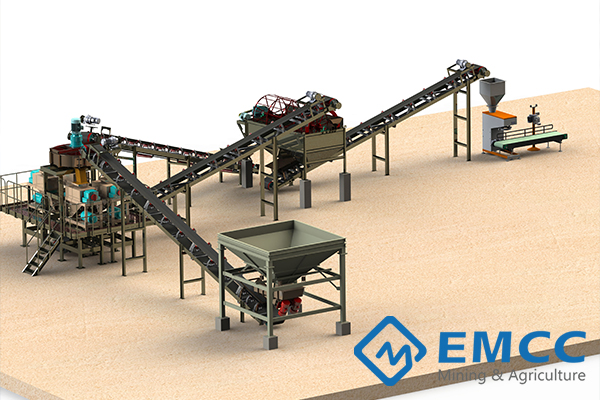

In fertilizer production, the fertilizer granular shall be screened before packaging to ensure the uniformity of the finished product. Rotary drum screen is a common equipment used in the fertilizer industry for compound fertilizer and organic fertilizer production. Rotary durm screen is mainly used in the fertilizer production line to separate finished product and returning materials. The fertilizer sieving machine can also be used for classifying the finished product.

Advantage

1. Adopt combined screen which is easy for maintenance and replacement.

2. High screening efficiency, reducing labor intensity.

3. The driving part adopts pin coupling, making it convenient for assembly and maintenance.

4. Reasonable structure, stable operation, no damage to the rotary machine.

5. Sealed dust cover is installed outside the rotary sieve, eliminating flying dust, improving the working environment.

6. The sealed dust cover also helps isolate the noise produced during operation.

7. Being used in organic & compound fertilizer production lines, behind fertilizer cooling machine.

Range of Application :

Rotary drum screen is used in many industries such as fertilizer production, steel making, mining, quarrying, foundries, food processing and chemical industry for the separating of bulk materials like compound fertilizers, organic fertilizers, stone aggregates, different kind of sand, active carbon and other materials.

Working principle

Rotary drum screen consists of five parts, including hexagonal drum, rack, funnel, reducers and motor. After the fertilizer granules go into the drum, it is screened by the rotating of the drum, and on the other hand, granules with large size move forward along the drums gradient, screened gradually through different screen.

Technical Parameters

Product detail pictures:

Related Product Guide:

Global Organic Compound Fertilizer Market 2018 Hanfeng, Kingenta, LUXI, STANLEY, WengFu Group, Hubei Xinyangfeng | Organic Fertilizer Plant

MBAC thriving in Brazil’s fertilizer sector | Organic Liquid Fertilizer Manufacturers

We provide fantastic energy in top quality and advancement,merchandising,gross sales and marketing and operation for Low MOQ for Plastics Recycling Granulator - Rotary Drum Screen – Exceed, The product will supply to all over the world, such as: Ukraine , Czech republic , Algeria , We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We've been able to also provide you with no cost samples to meet your needs. Best efforts are going to be produced to supply you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our items and enterprise. lot more, you'll be able to come to our factory to find out it. We'll constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. You should really feel absolutely free to make contact with us for small business and we believe we'll share the top trading practical experience with all our merchants.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.