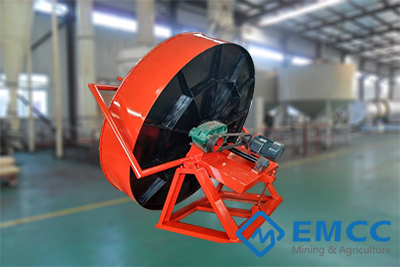

Hot-selling Disc Granulating Machine - New Type Organic Fertilizer Granulator – Exceed

Hot-selling Disc Granulating Machine - New Type Organic Fertilizer Granulator – Exceed Detail:

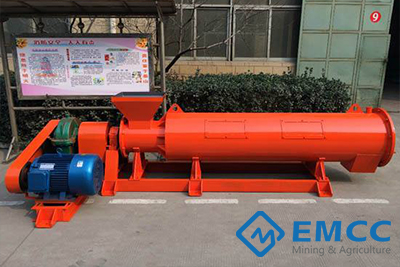

New type organic fertilizer granulator is also called wet granulator or stirring tooth granulator. It is a newly developed granulator used for granulating various kinds of fermented organic materials. The raw materials need not to be dried before granulation, saving energy and production cost. The granules produced by this fertilizer making machine are spherical type, which is easy to apply.

Advantage

1. Fertilizer granules produced are all spherical shaped, nice appearance and easy to apply.

2. Fertilizer granules produced have rich organic matter content, which can reach 100%, realizing pure organic matter granulation.

3. No binder need to be added during granulation, for the organic matter particles can grow inlaid with each other under certain force.

4. Fermented materials need not to be dried, the moisture content can be 20%-40%.

5. Fertilizer granules produced are solid so that not easy to be moistened.

6. The shell of fertilizer granulator adopts heavy seamless steel pipe, sturdy and durable, never deform. The stable base design ensures a more stable running.

7. High granulation rate which can reach 80%-90%, suitable for various formulations. The compressive strength of granular fertilizer produced is higher than that of disc fertilizer granulator and rotary drum granulator. Large granular rate is lower than 15%. The size and uniformity of granules can be adjusted by the stepless speed regulation function of the machine.

Working principle

New type organic fertilizer granulator consists of machine body, driving part and granulating rotor. The machine body and driving part are mainly fixed on a machine frame, ensuring the sturdy construction, stable performance and easy installation of the granulator machine.The motor and speed reducer of the driving part drive the rotor to rotate. After the materials enter into the organic fertilizer machine through the feeding inlet, by the high speed rotating mechanical stirring force and aerodynamic force thereof, the materials are mixed, granulated, spherified and densified in the machine, achieving the aim of granulation. The formed granules are pushed out in the other end of the equipment.

Note: The diameter of the produced granules can be controlled by adjusting the quantity of the raw materials and rotating speed of main shaft. The less the raw materials mixed and the higher the rotating speed, the smaller the granulated fertilizer.

Technical Parameters

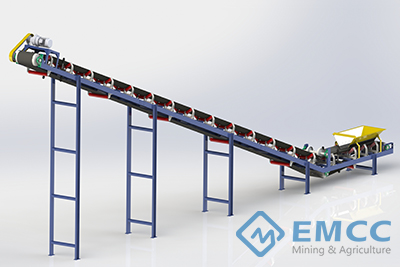

Product detail pictures:

Related Product Guide:

Fertiliser factory to be built in Kiambu by Slovakia investor | Fertilizer Wet Mixing Granulator

What organic fertilizers mean to plants and soil | Organic Fertilizer Plant

Our advantages are lower prices,dynamic sales team,specialized QC,strong factories,high quality products and services for Hot-selling Disc Granulating Machine - New Type Organic Fertilizer Granulator – Exceed, The product will supply to all over the world, such as: Singapore , Provence , Honduras , They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We have been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.