factory Outlets for Machine To Make Wood Pellets - Disc Mixer – Exceed

factory Outlets for Machine To Make Wood Pellets - Disc Mixer – Exceed Detail:

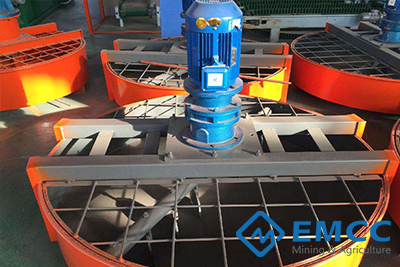

The disc mixer is mainly applied to the compound fertilizer plant. By using the optimum quality material and leading technology, this fertilizer mixing machine complies with industry standards and international specifications. It is popular with our customers due to its high efficiency, competitive price, easy operation and low maintenance cost. In the compound fertilizers production line, it is placed before the fertilizer granulator to uniformly mix the raw materials before the granulation.

Advantage

1. Robust structure. It is made of steel, resistant to abrasion, wear resistance, durable.

2. Design and rational configuration. PVC padded plate to avoid sticking the inner lining.

3. Cycloidal reducer, high speed and efficiency, energy saving.

4. Mixing and crushing material, easy to operate and unload materials.

5. Can work independently or match with the fertilizer plant.

Principle of Work

The entire mixing process is driven by the main shaft after starting the engine. There are several stirring blades welded on the main shaft and small shovels are placed on each stirring blade. Feed the fertilizers in the cylinder. It is the shovels and the agitation blades that play an important role in the homogeneous mixture of materials. Then open the discharge door to place the average mixed fertilizer. As the material is not very wet, it almost does not stick to the shovels or stirring blades, so it is not necessary to clean the machine.

Technical Parameter

Product detail pictures:

Related Product Guide:

No-Till Farmer Editors Share Top News Makers from National Farm Machinery Show | Organic Liquid Fertilizer Manufacturers

Global Sales of Fertilizer Additives to Witness a Surge in the Coming Years Owing to Increasing Demand for High-performance Fertilizers | Organic Fertilizer Plant

We have a professional, efficiency team to provide quality service for our customer. We always follow the tenet of customer-oriented, details-focused for factory Outlets for Machine To Make Wood Pellets - Disc Mixer – Exceed, The product will supply to all over the world, such as: Guyana , Lithuania , Saudi Arabia , To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!