Factory making Complete Wood Pellet Line - Disc Fertilizer Granulator – Exceed

Factory making Complete Wood Pellet Line - Disc Fertilizer Granulator – Exceed Detail:

Disc fertilizer granulator emerges with the development of fertilizer production.It is appropriate for granulating round fertilizer particles for compound or organic fertilizer for convenient transportation and storage.To produce nutritionally balanced fertilizer particles, the proper granulating machine is your top decision. We are professional fertilizer plant and will offer you practical guidance in fertilizer granulating. You can also spread atomizing NPK to increase nutritions in organic fertilizers during granulating.

Advantage

1. Arc structure ensures high granulating rate of 93%.

2. Novel and rational structure,light weight. Flexible granulating position.

3. Adjustable angle of large discs because of the pads.

4. Unique unpowered knives lowers down power consumption.

5. Large discs consists of disc body and disc joints. The disc joints can be accomodated upwards and downwards.

6. New dregging design and good granulating effects. Uniform granulators and most of the particles’ diameter is 3-5mm.

7. High working efficiency. It finishes disc granules at one stroke.

8. Simple operation, convenient maintenance and stable performance.

Range of Application :

Disc fertilizer granulator is the main equipment to make the round granules. It is mainly used in organic fertilizer industry by using materials with livestock and poultry manure,

grass meal, and so on. Disc fertilizer granulator is widely applied in coal dust industry,

cement industry, iron and steel industry and the chemical fertilizer industry

Working principle

Various dry powder materials are added from the top of the equipment, then being degassed, compressed and transported to arc shaped notch of those two rolls which are doing reversed rotation at a constant speed. Materials are condensed in the disc, reducing the stress-tolerant of materials which naturally separate with each other with the aid of gravity and surface tension.

Technical Parameters

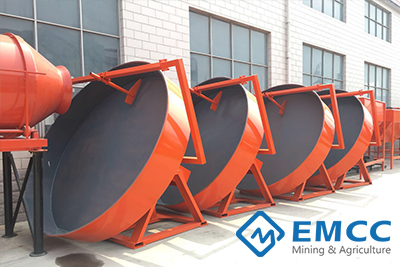

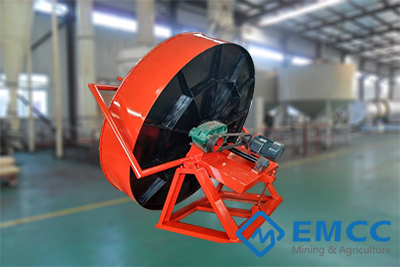

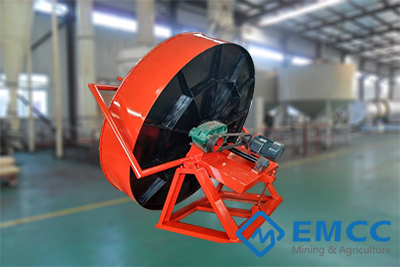

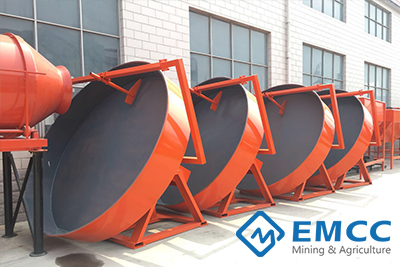

Product detail pictures:

Related Product Guide:

Itronics Starts R&D to Recover Tin, a U.S. Critical Mineral, and Copper From Silver Bullion Produced by Its “Breakthrough Technology” Printed Circuit Board Refining Pilot Plant Other OTC:ITRO | Organic Liquid Fertilizer Manufacturers

Seaweed Fertilizer Market Size Worth USD 17.1 Million by 2025: Hexa Research | Organic Liquid Fertilizer Manufacturers

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for Factory making Complete Wood Pellet Line - Disc Fertilizer Granulator – Exceed, The product will supply to all over the world, such as: Moldova , Libya , Rio de Janeiro , We are in continuous service to our growing local and international clients. We aim to be worldwide leader in this industry and with this mind; it is our great pleasure to serve and bringing the highest satisfaction rates among the growing market.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.