Factory made hot-sale Gypsum Roller Granulator - Double Roller Fertilizer Granulator – Exceed

Factory made hot-sale Gypsum Roller Granulator - Double Roller Fertilizer Granulator – Exceed Detail:

Double roller fertilizer granulator is a newly developed granulating machine in fertilizer industry. It uses squeezing principle to form fertilizer particles with diameters of 3.5-10mm in one time.It has higher granulating ratio of over 85%. Double roller fertilizer granulator is the most popular granulating methods in no-drying (2%-5% moisture content) fertilizer process at room temperature.Less cost and quick granulating,thus it can bring fertilizer investment a good economic returns.

Advantage

1.No-drying fertilizer such as 2%-5% moisture content fertilizer granulating process,forming fertilizer particles in one time,little cost.

2.Reliable motor adopted, no three wastes released,stable granulating,simple to maintain.

3.Rational structure and advanced technology,good economic benefits.

4.Wide application to raw materials like compound fertilizer,organic fertilizer,feed,etc. Can be used to process compound fertilizer of various concentrations(including organic fertilizer,inorganic fertilizer,biological fertilizer and magnetic fertilizer)

5.Popular in domestic fertilizer series production such as tombarthite fertilizer,ammonium bicarbonate fertilizer,ammonium persulfate fertilizer,etc.

Working principle

The Double roller fertilizer granulator is the representative of extrusion granulator. Dry materials are compressed into hard & dense blocks at a pressure, which is the Extruding Process. Block materials are crushed, screened and granulated later, which is the Granulating Process. The functions of extrusion are to squeeze the air between particles out, and to make the distance between particles near enough to give rise to interaction forces. The particle hardness of roller compaction granulation granules is formed mainly due to attraction between the molecules. Our double roller press machine is continuous extruding granulation of positive-displacement.

Technical Parameters

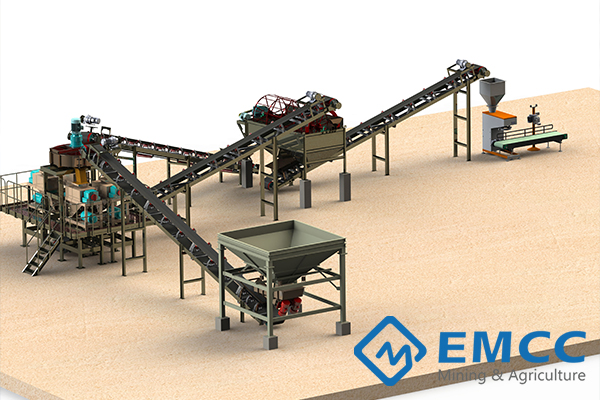

Product detail pictures:

Related Product Guide:

Fertiliser factory to be built in Kiambu by Slovakia investor | Fertilizer Granulating Machine

Anti-Caking Agents Market Professional Study and Research Report 2018-2028 | Organic Fertilizer Plant

We know that we only thrive if we could guarantee our combined price tag competiveness and quality advantageous at the same time for Factory made hot-sale Gypsum Roller Granulator - Double Roller Fertilizer Granulator – Exceed, The product will supply to all over the world, such as: Bolivia , Barcelona , Slovakia , In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.