Excellent quality Gypsum Fertilizer Granules Making Machine - Disc Mixer – Exceed

Excellent quality Gypsum Fertilizer Granules Making Machine - Disc Mixer – Exceed Detail:

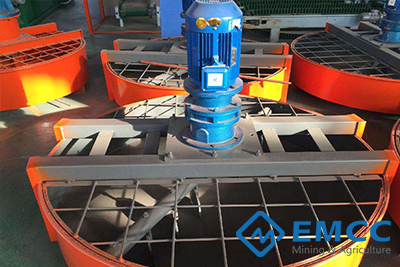

The disc mixer is mainly applied to the compound fertilizer plant. By using the optimum quality material and leading technology, this fertilizer mixing machine complies with industry standards and international specifications. It is popular with our customers due to its high efficiency, competitive price, easy operation and low maintenance cost. In the compound fertilizers production line, it is placed before the fertilizer granulator to uniformly mix the raw materials before the granulation.

Advantage

1. Robust structure. It is made of steel, resistant to abrasion, wear resistance, durable.

2. Design and rational configuration. PVC padded plate to avoid sticking the inner lining.

3. Cycloidal reducer, high speed and efficiency, energy saving.

4. Mixing and crushing material, easy to operate and unload materials.

5. Can work independently or match with the fertilizer plant.

Principle of Work

The entire mixing process is driven by the main shaft after starting the engine. There are several stirring blades welded on the main shaft and small shovels are placed on each stirring blade. Feed the fertilizers in the cylinder. It is the shovels and the agitation blades that play an important role in the homogeneous mixture of materials. Then open the discharge door to place the average mixed fertilizer. As the material is not very wet, it almost does not stick to the shovels or stirring blades, so it is not necessary to clean the machine.

Technical Parameter

Product detail pictures:

Related Product Guide:

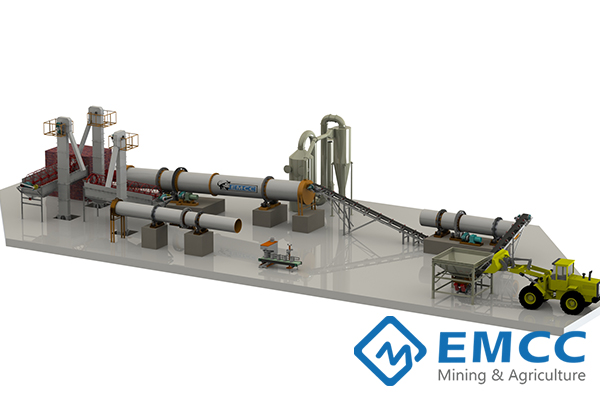

Tatarstan Fertiliser Complex, Volga Federal District | Organic Fertilizer Products

2018 Global Oil Shale Market Development, Business Outlook, Industry Research Analysis, Share, Growth Opportunities, Forecast 2025 | Organic Fertilizer Products

Having a sound small business credit score, outstanding after-sales services and modern manufacturing facilities, we've got earned an fantastic reputation among our buyers across the globe for Excellent quality Gypsum Fertilizer Granules Making Machine - Disc Mixer – Exceed, The product will supply to all over the world, such as: Montreal , Munich , Cyprus , Due to good quality and reasonable prices, our products have been exported to more than 10 countries and regions. We are looking forward to cooperating with all customers from at home and abroad. Moreover, customer satisfaction is our eternal pursuit.

We have been looking for a professional and responsible supplier, and now we find it.