Chinese wholesale Organic Fertilizer Pellets Production - Belt conveyor – Exceed

Chinese wholesale Organic Fertilizer Pellets Production - Belt conveyor – Exceed Detail:

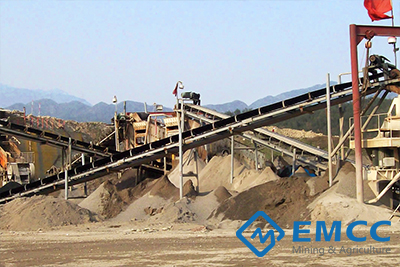

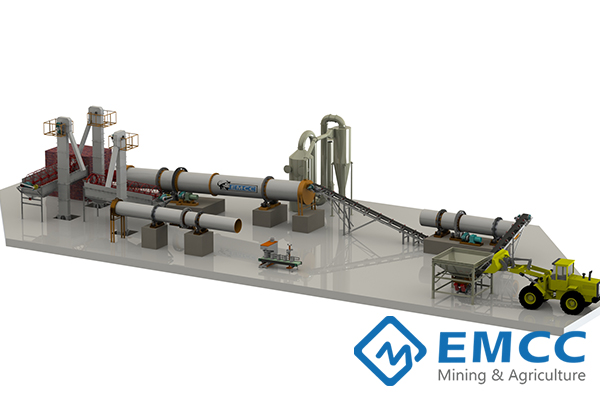

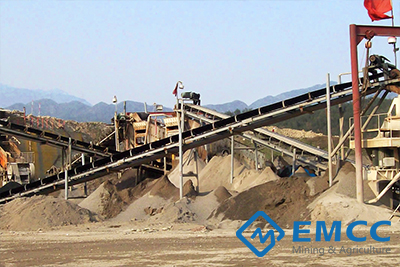

Belt Conveyor System is an indispensable part in the whole fertilizer production line. We provide customers with inclined belt conveyor and high inclination-angle belt conveyor. The inclined conveyor connects main fertilizer equipment together, making an easier raw materials & finished products transportation. The material handling conveyors are used in incline and decline applications to allow fertilizers to be accumulated while moving between floors or stacked conveyor. It saves labor, time and energy, with characters of high efficiency & easy operation. Inclined conveyor is widely used not only in compound & organic fertilizer production, but in wood & feed pellets production line, which is adjustable in accordance with customer demands. The material is discharged into the hopper of the conveyor. This intake hopper has rubber-closing plates to reduce material loss. When worn out, these plates can easily be removed. The inclined belt conveyor is built up of chopped stainless steel. The frame exists of sections that are bolted together. The conveyer belt is on hot sale.

Advantage

1. Compact design, suitable for grain, powder or fertilizer products.

2. Grooves used to fasten attachment parts, such as stands, side rails or proximity switches

3. Profile design ensures a torsion-resistant structure with good carrying characteristics

4. Crowned pivot rollers and idler rollers allow center belt run and facilitate belt adjustment

5. Optional rubberized drive rollers ensure optimal transmission of torque

Working principle

Belt conveyor is composed of rollers and closed conveyor belt. There are two rollers one is for driving conveyor rotating another one is for changing the motor direction of conveyor. Head roller is drived by motor conveyor is draged by force of friction which is generated from head roller and conveyor. Head roller is often set in the discharging end to increase traction for a better dragging. Material is fed from feed end and falls on the rotating conveyor belt and discharged by conveyor delivery end.

Technical Parameters

Product detail pictures:

Related Product Guide:

Global Organic Fertilizers Market: Factors Influencing The Growth Rate to 2023 | Organic Fertilizer Plant

Valentine’s Day 2019: Grow you own bouquet of cut flowers | Organic Fertilizer Plant

We also provide item sourcing and flight consolidation solutions. We have now our very own manufacturing facility and sourcing place of work. We could provide you with nearly every kind of merchandise associated to our merchandise variety for Chinese wholesale Organic Fertilizer Pellets Production - Belt conveyor – Exceed, The product will supply to all over the world, such as: Barcelona , America , Mombasa , We've a skilled sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with personalized service and unique merchandise.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.