Big discounting Ball Granules Making Equipment - Rotary Drum Screen – Exceed

Big discounting Ball Granules Making Equipment - Rotary Drum Screen – Exceed Detail:

In fertilizer production, the fertilizer granular shall be screened before packaging to ensure the uniformity of the finished product. Rotary drum screen is a common equipment used in the fertilizer industry for compound fertilizer and organic fertilizer production. Rotary durm screen is mainly used in the fertilizer production line to separate finished product and returning materials. The fertilizer sieving machine can also be used for classifying the finished product.

Advantage

1. Adopt combined screen which is easy for maintenance and replacement.

2. High screening efficiency, reducing labor intensity.

3. The driving part adopts pin coupling, making it convenient for assembly and maintenance.

4. Reasonable structure, stable operation, no damage to the rotary machine.

5. Sealed dust cover is installed outside the rotary sieve, eliminating flying dust, improving the working environment.

6. The sealed dust cover also helps isolate the noise produced during operation.

7. Being used in organic & compound fertilizer production lines, behind fertilizer cooling machine.

Range of Application :

Rotary drum screen is used in many industries such as fertilizer production, steel making, mining, quarrying, foundries, food processing and chemical industry for the separating of bulk materials like compound fertilizers, organic fertilizers, stone aggregates, different kind of sand, active carbon and other materials.

Working principle

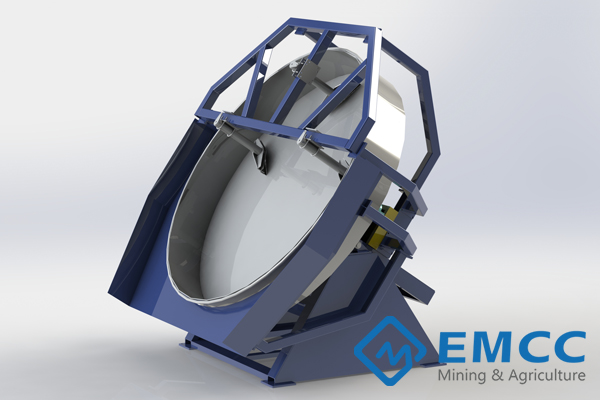

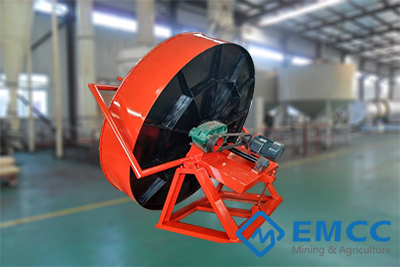

Rotary drum screen consists of five parts, including hexagonal drum, rack, funnel, reducers and motor. After the fertilizer granules go into the drum, it is screened by the rotating of the drum, and on the other hand, granules with large size move forward along the drums gradient, screened gradually through different screen.

Technical Parameters

| Model | Working speed (r/min) | Installation Angle (°) | Capacity (t/h) | Reducer model | Power (kw) |

| GTS-1020 | 21 | 2-2.5 | 1-2 | ZQ250 | 3 |

| GTS-1030 | 21 | 2-2.5 | 2-3 | ZQ250 | 3 |

| GTS-1240 | 18 | 2-2.5 | 3-5 | ZQ250 | 4 |

| GTS-1540 | 16 | 2-2.5 | 5-8 | ZQ350 | 5.5 |

| GTS-1560 | 16 | 2-2.5 | 6-10 | ZQ350 | 5.5 |

| GTS-2080 | 12 | 2-2.5 | 10-20 | ZQ450 | 11 |

Product detail pictures:

Related Product Guide:

Fermented Plant Extracts Market Progresses for Huge Profits During 2017 – 2025 | Organic Liquid Fertilizer Manufacturers

Digital Publishing And Content Streaming Top Manufacturers and Uses | Organic Liquid Fertilizer Manufacturers

With our loaded practical experience and thoughtful solutions, we now have been identified for a trusted provider for numerous intercontinental consumers for Big discounting Ball Granules Making Equipment - Rotary Drum Screen – Exceed, The product will supply to all over the world, such as: Egypt , Armenia , Karachi , If you give us a list of products you are interested in, along with makes and models, we can send you quotations. Please email us directly. Our goal is to establish long-term and mutually profitable business relationships with domestic and overseas clients. We look forward to receiving your reply soon.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!