Best quality Complete Wood Pellet Production Line Price - Disc Mixer – Exceed

Best quality Complete Wood Pellet Production Line Price - Disc Mixer – Exceed Detail:

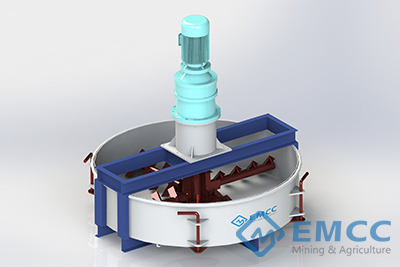

The disc mixer is mainly applied to the compound fertilizer plant. By using the optimum quality material and leading technology, this fertilizer mixing machine complies with industry standards and international specifications. It is popular with our customers due to its high efficiency, competitive price, easy operation and low maintenance cost. In the compound fertilizers production line, it is placed before the fertilizer granulator to uniformly mix the raw materials before the granulation.

Advantage

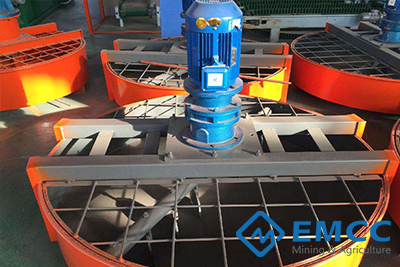

1. Robust structure. It is made of steel, resistant to abrasion, wear resistance, durable.

2. Design and rational configuration. PVC padded plate to avoid sticking the inner lining.

3. Cycloidal reducer, high speed and efficiency, energy saving.

4. Mixing and crushing material, easy to operate and unload materials.

5. Can work independently or match with the fertilizer plant.

Principle of Work

The entire mixing process is driven by the main shaft after starting the engine. There are several stirring blades welded on the main shaft and small shovels are placed on each stirring blade. Feed the fertilizers in the cylinder. It is the shovels and the agitation blades that play an important role in the homogeneous mixture of materials. Then open the discharge door to place the average mixed fertilizer. As the material is not very wet, it almost does not stick to the shovels or stirring blades, so it is not necessary to clean the machine.

Technical Parameter

| Model | Dimension

(mm) |

Disc Depth

(mm) |

Disc Diameter (mm) | Power

(kw) |

Mixing Speed

(r/min) |

Capacity

(t/h) |

| PJ-1600 | 1600x1600x1800 | 400 | 1600 | 7.5 | 16 | 2-4 |

| PJ-1800 | 1800x1800x1800 | 400 | 1800 | 7.5 | 16 | 3-5 |

| PJ-2000 | 2000x2000x1800 | 400 | 2000 | 7.5 | 16 | 4-6 |

| PJ-2200 | 2200x2200x1850 | 400 | 2200 | 7.5 | 16 | 6-8 |

| PJ-3000 | 3000x3000x2000 | 400 | 3000 | 15 | 16 | 8-12 |

Product detail pictures:

Related Product Guide:

Two minute briefing: Polyhalite and Sirius Minerals | Organic Liquid Fertilizer Manufacturers

2018 Global Oil Shale Market Development, Business Outlook, Industry Research Analysis, Share, Growth Opportunities, Forecast 2025 | Organic Fertilizer Products

We will make just about every exertion for being excellent and perfect, and speed up our actions for standing during the rank of worldwide top-grade and high-tech enterprises for Best quality Complete Wood Pellet Production Line Price - Disc Mixer – Exceed, The product will supply to all over the world, such as: Lahore , Palestine , Somalia , As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!