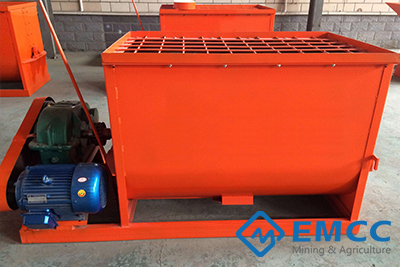

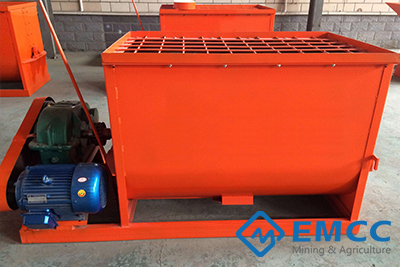

Best Price on Wet High Shear Granulator - Horizontal Fertilizer Mixer – Exceed

Best Price on Wet High Shear Granulator - Horizontal Fertilizer Mixer – Exceed Detail:

The horizontal fertilizer mixer, which is the new-generation mixing equipment developed by our factory, is high mixing uniformity, less material residual. This kind of fertilizer mixing machine is suitable for blending the formula feed, concentrated feed, additive premix, and raw materials of organic and compound fertilizer

Advantage

1.Multifunctional.Applied to many heavy industry fields such as chemicals,pharmacy,food,fertilizer,dyestuff,construction materials,resin glass,ect.

2.High mixing speed and uniformly mixing,low noise.

3.Reduction gears is matched to make sure stable mixing.

4.Carbon steel materials,durable and simple maintenance cost.

5.Low energy consumption,simple operation.

Range of Application :

This kind of fertilizer mixing machine is suitable for blending the formula feed, concentrated feed, additive premix, and raw materials of organic and compound fertilizer.

Working principle

1. Ensure to check whether the bolts are loose or not before starting the machine.

2. To check the bearing block and reduction drive. To see if their oil level is in place.

3. It is strictly prohibited that the materials with the big stone, big iron and etc, to avoid damaging the mixing blade.

4. Before stopping the machine, we should first stop feeding materials. It forbids to stop the machine with materials in it.

5. Starting the main motor, to check if the direction of rotation is opposite. If opposite, stop and adjust the machine immediately.

6.This machine should be started under the circumstance of zero load. It is strictly forbidden to put raw materials in the mixer before it rotating, to avoid damage to the machine.

7. Widely used in flat die granulator production line and new type organic fertilizer production line

Technical Parameters

Product detail pictures:

Related Product Guide:

Here are the secrets to getting those big, blue hydrangea blooms | Organic Fertilizer Plant

Tatarstan Fertiliser Complex, Volga Federal District | Fertilizer Wet Mixing Granulator

We've got a really efficient group to deal with inquiries from prospects. Our purpose is "100% customer fulfillment by our product excellent, price & our group service" and enjoy a superb track record amid clientele. With many factories, we can easily deliver a wide selection of Best Price on Wet High Shear Granulator - Horizontal Fertilizer Mixer – Exceed, The product will supply to all over the world, such as: Surabaya , Johannesburg , Las Vegas , Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!