BB Fertilizer Production Line

BB FERTILIZER PRODUCTION LINE

BB fertilizer is a compound fertilizer produced by mixing two or more straight fertilizers through mechanical processing. It has the characteristics of low cost and high nutrient concentration. Its nutrient ratio can be flexibly adjusted according to the soil and crops, which can further improve fertilization levels.

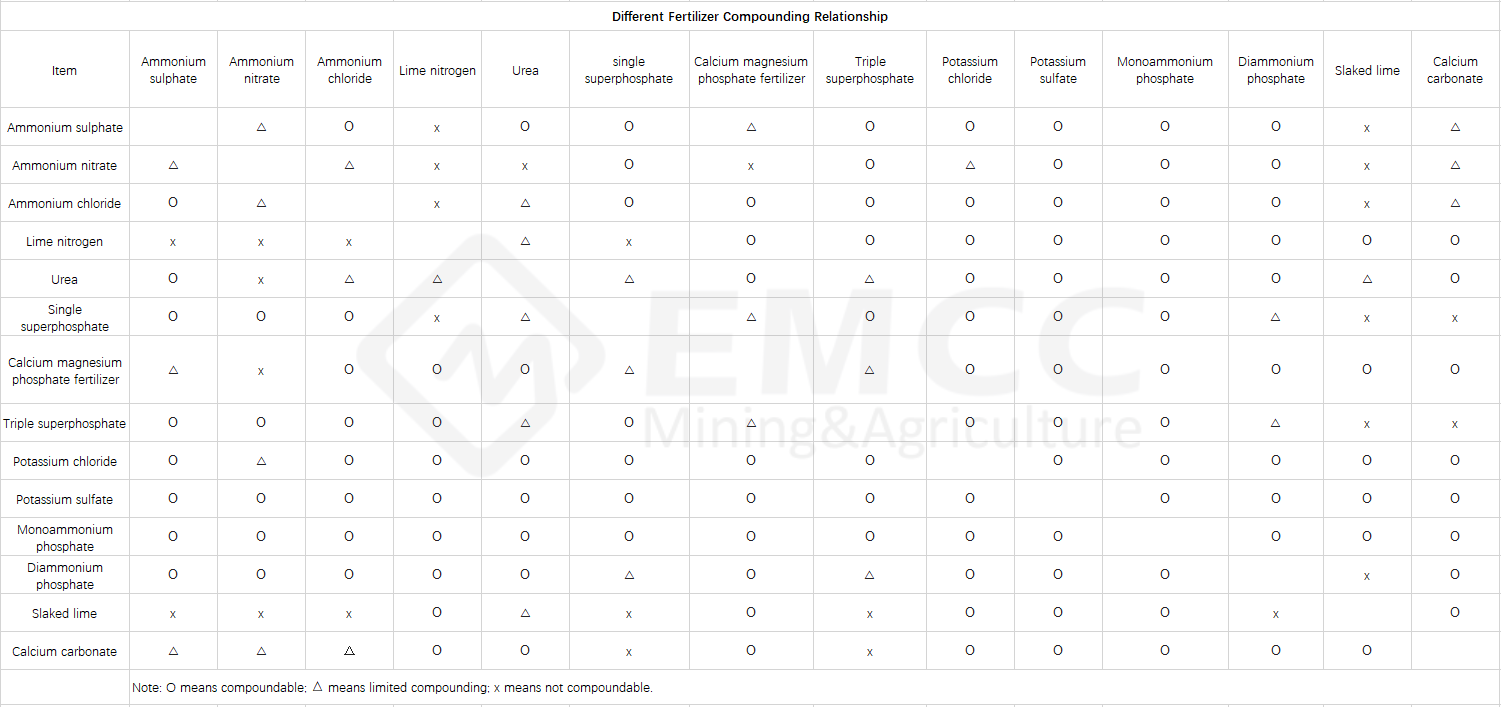

The quality of BB fertilizers greatly depends on the chemical reactions that occur during the fertilizer mixing process, moisture conditions and ambient temperature. As the temperature rises and the water vapor saturation increases, the chemical reactions between the components accelerate, which will reduce the fertilizer quality. Therefore, when blending, attention should be paid to the physical and chemical properties of fertilizers and the corresponding conditions required for blending.

BRIEF DESCRIPTION

Manual feeding-automatic batching according to the set formula-automatic conveying-automatic mixing according to the set time-automatic packaging according to the set weight- Manual bag putting -automatic bag sealing and cutting

CHARACTERISTICS

Batching system: Automatic arc gate feeding device, arc gate feeding is two-stage feeding, which can accurately meet the proportion of materials. Static metering hopper metering (static metering hopper metering is a more practical and advanced metering method, batching speed is fast, the measurement accuracy is high.)

Conveying system: adopts bucket skirt belt, stable operation and convenient maintenance.

Mixing system: The latest double shaft gravity free mixer is a mixing device specially developed for BB fertilizer. It reaches the leading level, no damage on the granular material, and mixing more evenly. The special integrated motor reducer drives the double shaft. Compared with gears, chains and other transmission modes, the double reducer runs smoothly, less failure rate and vibration.

Packing system: All stainless steel packaging scales are used, with large packaging capacity, stable operation, and high packaging accuracy up to 2‰.

Control system: The touch screen is easy to operate, and the operating status of the equipment can be viewed in real time. 9 commonly used formulas can be set and of functions such as fault alarm, material interruption shutdown, etc..

QUALITY CONTROL POINTS

The batching part is the key to ensure the content of the product, so the verification work before starting the production line must be rigorously carried out. The automatic mixing part is the element that determines the uniformity of the material. The automatic quantitative packaging part determines weight of the finished product. Therefore, the staff for this part should be familiar with the operation of the meter, carefully observe the display of the meter value, adjust the meter parameters timely, and pay attention to some subtle matters. The factors which cause the reduce of packaging accuracy :such as the accuracy of the calibration scale, the vibration on packaging scale caused by other equipment, the non-uniform force on the sensor. And the contact with the packaging bag manually put will also cause weight deviation, which affect the accuracy of packaging.

THE FOLLOWING LISTS THE MIXING RATIO OF COMMON FERTILIZERS