Rotary Drum Cooler

DRUM COOLER

EMCC’s cooling machine can be customized according to customers’ different product needs to achieve the best results.

After drying, fertilizer temperature will be higher. If the fertilizer is directly packed without cooling, it will cause moisture absorption and caking, affecting product quality. So cooling equipment must be set in the actual production. At present, rotary drum cooling machine the most commonly used cooling equipment.

WORKING PRINCIPLE

The rotary drum cooling machine working principle is that under the action of cold air or ambient air, the material rolls in the rotating drum. The drum is set at a slight horizontal tilt to allow the material to pass through the cooling machine under gravity. During the drum rotation, the lifting plate maximizes the heat transfer efficiency by lifting the material and dropping it through the cold air.

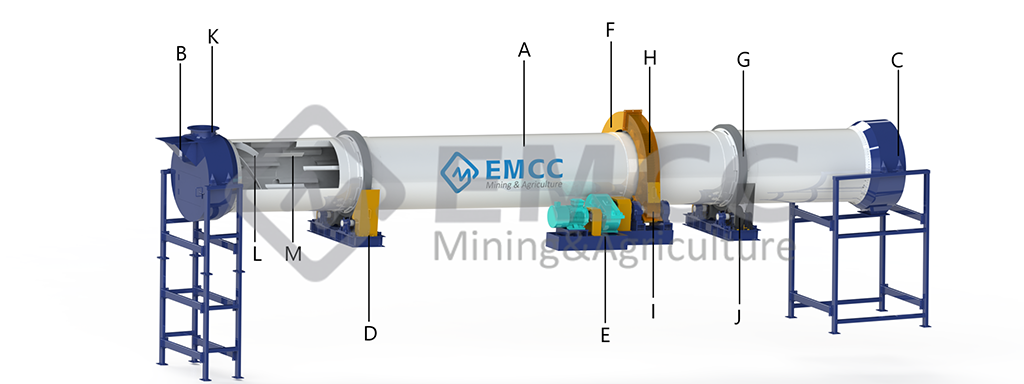

Rotary drum cooling machine is an inclined horizontal rotary cylinder, with a supporting device, a transmission device, a cylinder and a sealing structure such as inlet and outlet device.

After the dried granular fertilizer entering the cooling machine from the feed tube, it rotates with the rotation of the cylinder. There are lifting plates inside the cylinder, so that the material is evenly spread downward to form a material curtain, and the cold air drawn from the head enters the machine and contacts with the material for heat exchange to cool it. The cold air brings the fertilizer’s heat out of the system, bringing its temperature down to below 40 degrees.

FEATURES

Diameter: 0.8– 4.6m (2.625′ – 15.092′)

Capacity: 1 TPH – 200 TPH

The lifting device designed according to the specific situation can maximize the thermal conductivity between the material and the cold air flow.

A variety of materials are available, stainless steel optional for long service life

COOLING MACHINE COMPONENTS

APPLICATIONS & MATERIALS

The rotary drum cooling machine is the most important cooling equipment in industrial cooling. It can handle a variety of raw materials and it is suitable for almost any industry requiring industrial cooling solutions, such as: