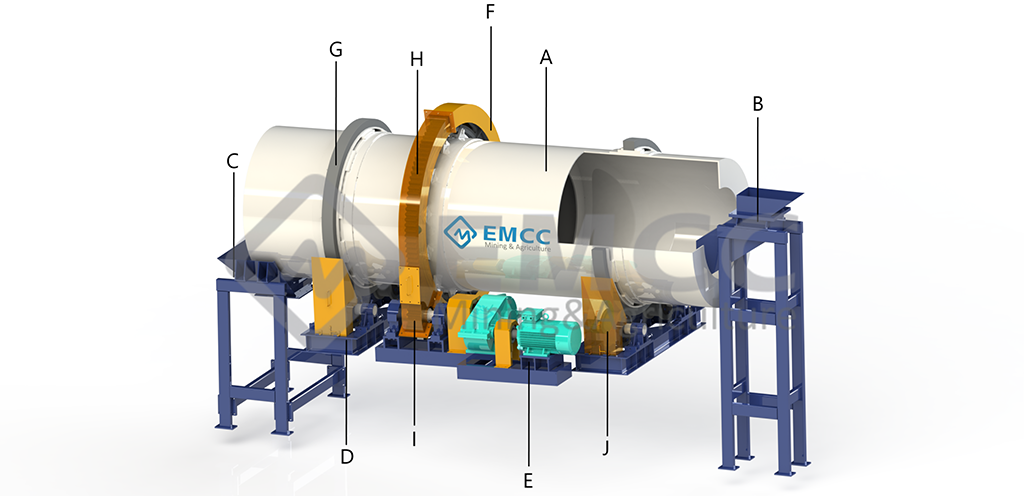

Rotary coating machine

COATING MACHINE

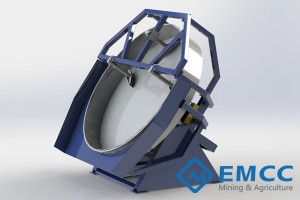

To reduce the agglomeration of finished fertilizer particles, improving the fertilization effect, or to meet the consumer preferences of certain specific markets, it is necessary to add different colors to the surface of fertilizer particles. Therefore, after the finished fertilizer is cooled, most manufacturers will add a coating process before packing

WORKING PRINCIPLE

Strip-shaped shovelling plates are welded inside the middle shell of the coating machine, and the strip-shaped shovelling plates can make the particles flip inside the machine.

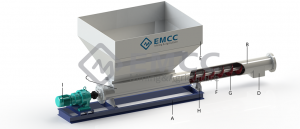

If liquid coating agent needs to be sprayed, EMCC can equip corresponding tanks and pumps. And the liquid nozzle extends into the cylinder from the end of the drum for spraying.

If powder coating agents need to applied, such as diatomite, kaolin, lime, etc., they will be fed into the coating machine by a screw feeder. When the coating machine rotates, the fertilizer particles surface will be wrapped with a hard shell. The finished particles produced in this way have a good appearance and do not break when transported, making them more suitable for storage.

The appearance of the coating machine is the same as that of the dryer and cooler. It is an inclined horizontal rotary cylinder with a supporting device and a transmission device.

FEATURES

Diameter: 0.8– 2.5m (2.625′ – 8.202′)

Capacity: 1 TPH – 200 TPH

A variety of materials are available, stainless steel optional for long service life

COATING MACHINE COMPONENTS